Crude oil produced in the fields heavily consists of water in the form of an emulsion that requires to be treated. Extracted crude oil normally contains salts, Chlorides of sodium, calcium, and magnesium.

If crude oil is left untreated before processing, salt present in crude oil can cause many types of operating failure and maintenance problems. Crude oil Desalter is an important part of the refinery that helps to clean crude oil in its initial processing stage.

Before processing crude oil in the heater and stating its separation process in Crude or Vacuum column every oil refinery needs to process crude oil through desalter. In this article “Crude oil Desalter” you will learn:

- What is desalter and why it is important.

- Working principle of Desalter and Its transformer.

- Process scheme of desalter

- Type of desalter and its component

- Frequently used desalter related terms and

- Variable that affect the efficiency of desalter in crude processing.

Featured Article: Heat Tracing in Piping: Types, Working, Use, Installation, Comparison

Table of Contents

What is Crude oil Desalter?

Desalting is a water-cleaning process performed at the initial stage in crude oil refineries. The equipment used to clean crude oil is called desalter.

In other words, Desalter is processing equipment in the refinery that removes salt and other impurities from crude oil. Desalter in a refinery is one of the major components. It is typically the first unit towards cleaning and processing crude oil and its distillation.

This equipment of refinery is of shape like a vessel on which transformers are installed for the purpose of the emulsifying mixture of crude oil and emulsifying agent mixed to it for crude oil cleaning. Desalters are generally mounted on the civil or structural base.

Why Desalter is important?

The main purpose of desalter is to remove undesirable impurities from crude oil before processing it for distillation. The most concerning points for removing impurities from crude oil are as follows:

- Inorganic impurities like chlorides of sodium, calcium, and magnesium can be decomposed in the Heating unit and Hydrogen Chloride will be formed which can get condensate to Hydrochloric Acid.

- This formation of hydrochloric acid may cause corrosion to other equipment and piping systems resulting in less life span than expected.

- By-products of Salts present in crude oil can cause plugging of the heat exchanger, column trays, coils of heat, and also they can cause corrosion to any surface they contact.

- Sand or Mud present in crude oil can damage Pumps and piping systems and will require more maintenance.

Advantage of Desalter in oil production

The basic benefits of desalter for crude oil are as follows:

- Cleaning of crude increases flowability in pipes, Pumps, Heat exchangers, etc.

- Less plugging and choking of equipment and piping system.

- No formation of scale in the Heat exchanger and heating unit

- Less corrosion in the Heat exchangers, distillation towers, Piping systems, etc.

- Less maintenance for pumps because of removal of mud, sand, and other impurities.

- Saving of oil from waste crude.

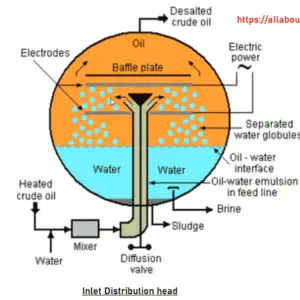

Desalter working principle

Crude oil received after transportation includes many types of salt traps in small droplets of water staggered all locations of the volume. These droplets are so small that self-extraction and settling are not possible. In general, there are 03 types of oleophobic Impurities found in crude oil:

- Salt: Mainly chlorides and Sulphates of Sodium (Na), Potassium (K), Calcium (Ca), and Magnesium (Mg).

- Sediments: Such as silt, sands, Mud, Iron oxide, and Sulphides.

- Water: Present as soluble, emulsified, and finely dispersed form.

Apart from above mention impurities crude oil also have some Oleophilic impurities but Desalter basics work to clear those 03 types of impurities for crude oil cleaning. The basic principle to wash the salt from crude oil is called Desalting. This Desalting process is done in two steps:

- 1st Step is to dilute the dispersed water-soluble salt content with fresh water

- 2nd Step is to remove diluted dispersed brine from crude oil.

For the First Stage of desalting, The crude oil is heated up to 120ºC to 140ºC then freshwater is added in crude oil in the amount of 4%-8% (Vo/Vo) with demulsifying chemicals or Effluent.

Desalter effluent composition is consists of many things such as:

- brine washing water used for removing salt, sand and

- Mud washing water jet used at periodic intervals, connate water produced from the reservoir with crude oil.

After adding Wash water to Crude oil a proper mixing is done that collects all small droplets of staggered brine into bigger drops.

In the Second Stage, Water or brine collected is drained out effluent system, and Cleaned Desalted oil is processed to preheat train for further processing.

Method of Desalting of Crude Oil

This Complete process of desalting can be in 03 ways:

- Mechanical: Here heated crude mixed with wash water left in a large vessel for settle down water drops because of gravity. This not so effective way and takes too much time.

- Chemical: In this method Surfactant or emulsion breakers are mixed with wash water to expedite the process of settling water. This also works on the gravity settling technique but because of the mixing of Emulsion breakers process is respectively quick but no so effective though.

- Electrical Desalting: This works on the method of the electric field where an attractive force is generated because of High voltage field application. As water is a bipolar Substance its attractive force development attracts all water molecules to get collected and converted into bigger water drops which further drain out.

Desalter transformer working principle

“When two immiscible liquids in which, One is electrically conductive and another non-conductive pass through a high-intensity electric field, The conductive liquid coalesces into large droplets“

This Phase separation fundamental of physics is the basic working principle of transformer is used in Salt and water separation from crude oil. In crude oil-water emulsion water mixed with salt content is an electrically conductive liquid and oil is non-conductive.

When 15000-16500 volts of current passes through oil-water emulsion water droplets begin to accumulate and separate from the oil-water interface.

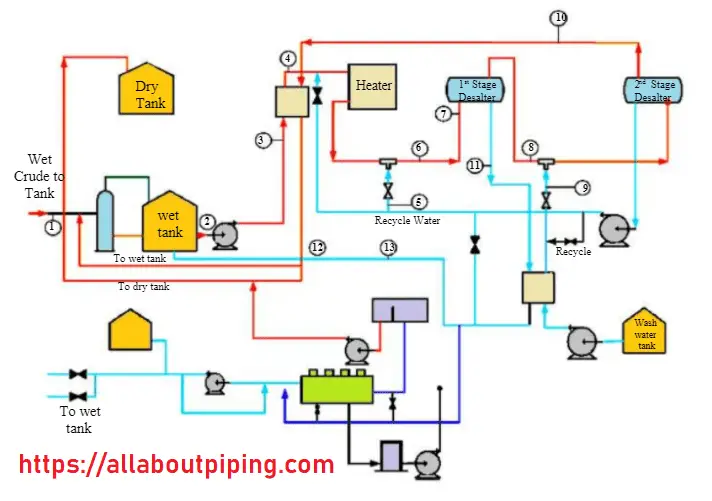

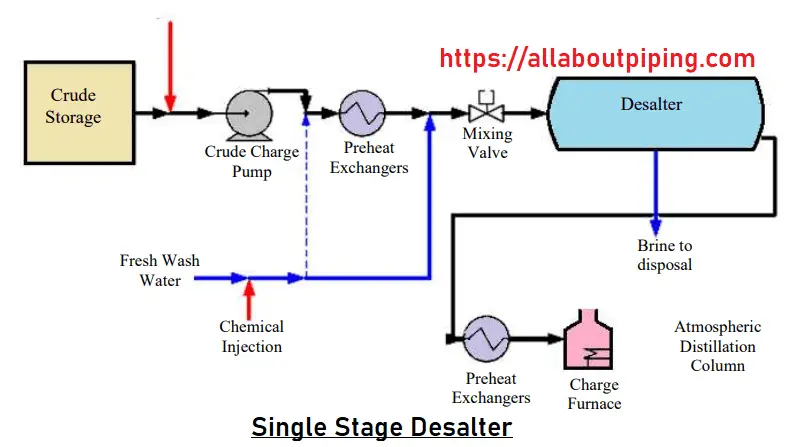

Process Scheme of Desalter

A typical process scheme is illustrated as follows:

- Wet crude flow to wet tank.

- Demulsifier / Chemical injection.

- Crude flow to the heat exchanger.

- Flow to the heater.

- Wash water recycled from 2nd stage vessel.

- Flow to 1st stage desalting mixing valve.

- Mixed fluid to 1st stage vessel.

- Flow to 2nd stage desalting mixing valve.

- Freshwater from the oil-water heat exchanger originated from the wash water tank.

- Treated crude flow.

- Effluent water from 1st stage Desalter vessel to water treatment plant and/or disposal pit.

- BS&W Analyzer – A signal to diverting Valve.

- Formation (free) water settled down at the bottom of the wet tank, to the water treatment plant and/or disposal pit

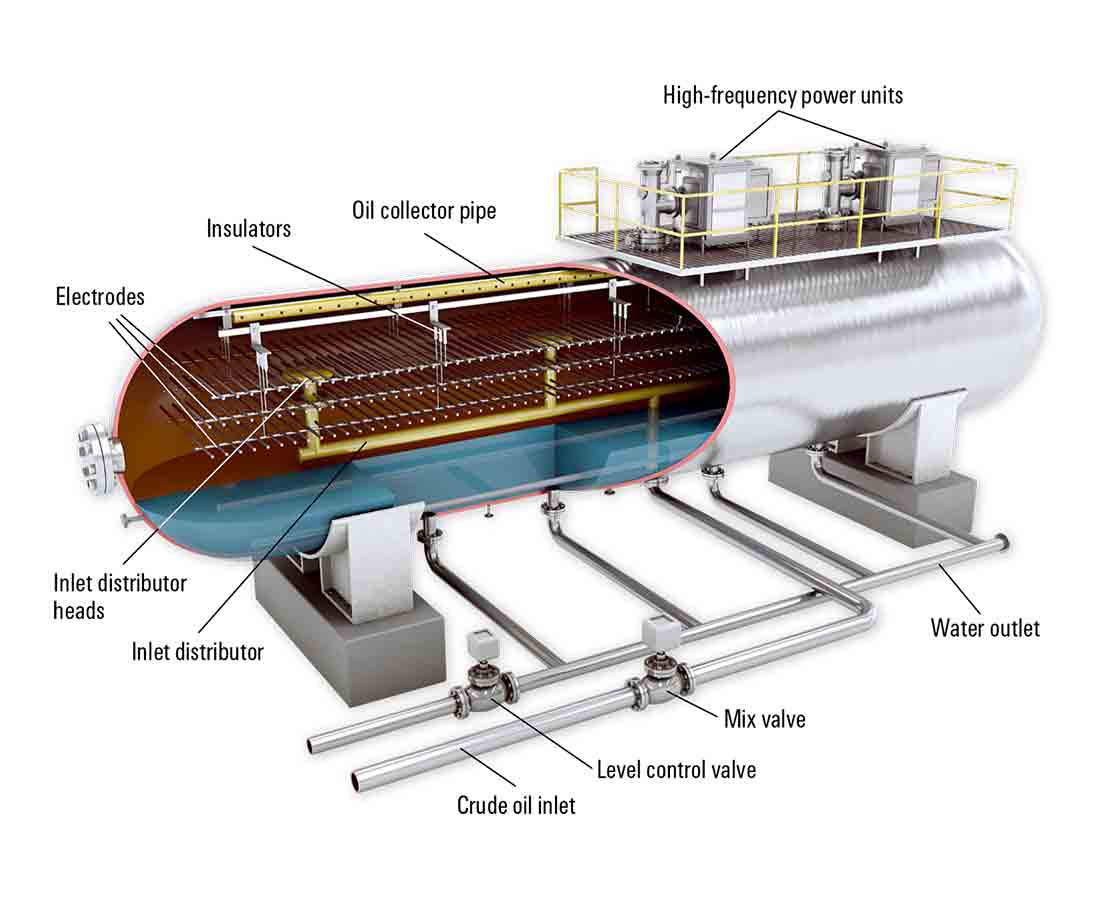

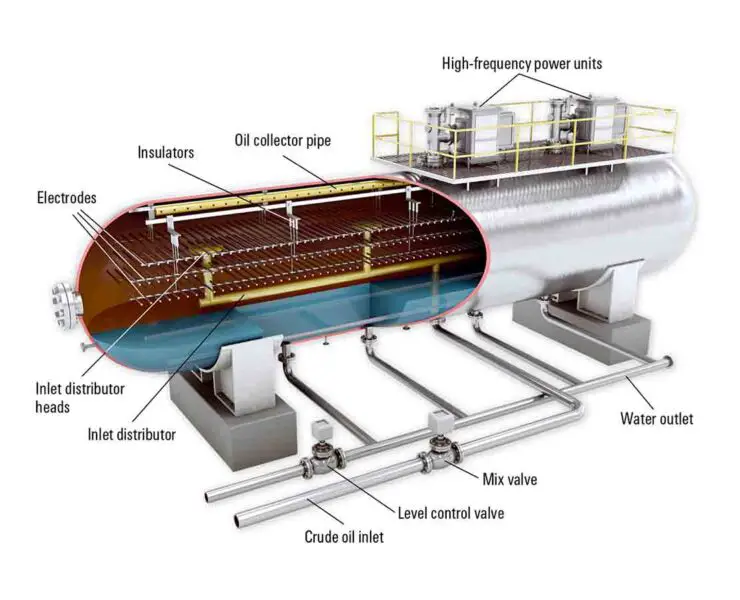

Electric Desalter Components

Components of electric desalter are as follows:

- High-Frequency Power Unit: This power transforming unit mounted on top of the desalter creates a high-frequency voltage in the Water-Oil mixture for Waterdrop coalescence.

- Oil collector Pipe: After separation of Oil and Water. A separate layer of Oil forms on top of the emulsion which collected by Oil collector pipe. It is installed in the topmost part inside the desalter.

- Insulators: These are components of desalter which insulate electrodes from other parts of desalters.

- Electrodes: Power transmitted from Transformer are distributed through Electrodes in Oil-water mixture.

- Inlet distributor: This is the main header pipe connected to the Inlet distributor heads.

- Inlet distributor heads: these are branches from the inlet distributor header which distribute oil-water emulsion into the desalter tank.

- Crude oil inlet: This is the piping system that allows crude to enter in the Inlet distributor header.

- Mix Valve: This valve connected to crude oil inlet piping allowing or isolating crude flow into the desalter. This is also a common valve for freshwater inlet line chemical injection systems. In short, This valve allows the creation of a mixture of Crude oil, water, and demulsifying agent.

- Water Outlet: This is the drainage of the desalter vessel which allows water to exit from the desalter system.

- Level control valve: This is a valve connected to a water outlet piping system that controls the level of water inside the desalter vessel.

- Desalter Feed Pump: Pumps sucking crude oil from preheating train and pumping to desalter.

Types of Desalter

According to the processing of crude oil and water mixture for cleaning and desalting, there are two types of the desalter present:

- Single-stage Desalter: This type of desalting unit has a single vessel to process the crude oil-water mixture for removing oleophobic impurities from crude oil. In single-stage desalter water, the intake ratio is about 5%-7%.

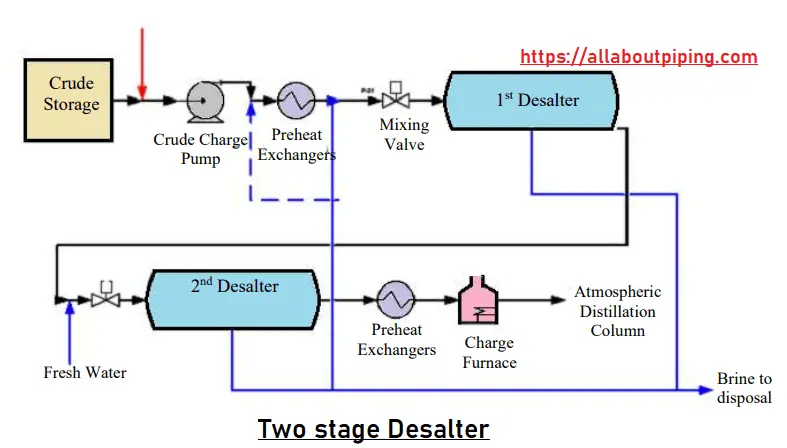

- Two-Stage Desalter: Field desalting requires water in some required percentage to efficiently process the cleaning of crude oil. But in places where freshwater has some scarcity, two-stage desalters are used.

In this desalting method, an Oil-water mixture enters 1st desalting with the mixing of emulsifying agents only. With the application of high voltage current in the mixture of 1st stage, some amount of staggered saline water accumulates and transferred to 2nd stage desalting vessel which 3%-4% wash water is mixed into the emulsion for further processing and desalting method.

Desalter related Terms

Terminologies related to desalter and its operational processing are as follows:

- Gravity separation: refers to the primary free settling of water and is related to the residence time that takes place in both settling tanks and desalting vessels.

- AC: Alternating electrical current

- Desalination: Process of removing salts from water sources

- Fouling: The reduction in performance of process equipment (heat transfer tubing, membranes, etc.) that occurs as a result of scale buildup, biological growth, or the deposition of colloidal material.

- Membrane: In desalting, used to describe a semipermeable film. Membranes used in electrodialysis are permeable to ions of either positive or negative charge. Reverse osmosis and nanofiltration membranes ideally allow the passage of pure water and block the passage of salts

- Precipitate: A substance separated from a solution by chemical or physical change as an insoluble amorphous or crystalline solid.

- Wash Water: Freshwater added to crude oil for desalting purposes.

- Saline water: Water with dissolved solids exceeding the limits of portability. Saline water may include seawater, brackish water, mineralized ground, and surface water, and irrigation return flows.

- Salt diffusion: The movement of ions or molecules under influence of a concentration difference.

- Solubility: A measure of the maximum amount of a certain substance that can dissolve in a given amount of water, or other solvents, at a given temperature.

- Specific conductance (conductivity): Quantitative expression for the capability of a particular solution to conduct electricity. It is defined as the conductance of a cube of that particular water that is 1 cm long and has a cross-sectional area of 1 cm2. Conductivity is usually expressed in micromhos per centimeter.

- Stage: A unit of desalting equipment capable of purification and separation of the feed water into product and concentrate. If separation is insufficient, more than one stage can be arranged in series

- Turbidity: Opaqueness or cloudiness caused by the presence of suspended particles in water, usually stirred-up sediments. The turbidity of water is measured by its capacity for absorbing or scattering light.

- S&W content: Oil, as produces from the well and production equipment, may contain considerable amounts of brine, as well as solid materials. The water solids content is referred to as sediment and water (S&W) or basic sediment and water (BS&W).

- Demulsifier: or demulsifying chemicals are a mixture of chemicals used to break the emulsion by destroying a weakening the stabilizing film around the dispersed droplets.

- Electrodes or grid: plates or rods used to establish the electric field in electrostatic treaters.

- Electrostatic treated: treater using electric fields in the oil coalescing area.

- Emulsifier: in addition to oil and water, a third substance called an emulsifier or emulsifying agent must be present for a stable emulsion to be produced. The emulsifiers usually exist as a film on the surface of the dispersed droplets.

- Emulsion: a combination of two immiscible liquids. One liquid is broken into droplets and is known as the discontinuous, dispersed, or internal phase. The liquid that surrounds the drops is a continuous or external phase.

- Interface: the contact surface between the boundaries of the two immiscible liquids. For e.g., the surface area between water droplets and the surrounding oil or the surface between separated crude and water in a vessel.

- Water-in-oil (w/o) emulsion: Crude oil emulsions nearly always consist of water drops dispersed in a continuous oil phase. This type is also called a regular or normal emulsion.

- Oil-in-water (o/w) emulsion: an emulsion consisting of oil drops dispersed in a continuous water phase. This do-called reverse emulsion often occurs on wastewaters and produced brines. The water content is generally greater than 85 volume percent.

- Desalting: Reducing the salt content of crude oil by diluting the entrained/emulsified water and then dehydrating.

- Dehydration: Removing water droplets or S&W or BS&W from crude oil (sometimes called treating)

- Wetting: refers to the adhesion or sticking of a liquid to a solid surface. If the solid surface (grain of reservoir rock, fines, etc.) is covered preferentially by oil, the surface is called oil wetted. Conversely, if water is preferentially attracted, the surface is water wetted.

More to Read: Common Abbreviations used in Piping

Variable effecting Desalter Efficiency

There are some factors that affect desalter efficiency. these variable works very effectively towards desalter optimization are:

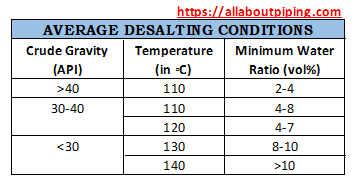

- Temperature: For an effective desalting temperature of the crude oil-water mixture must have an optimum temperature in the range of 120ºC to 140ºC. If temperature increase more than the optimum range oil becomes conducting and the basic principle of the desalting method will not work. again if the Temperature decreases below optimum temperature won’t reach the minimum required viscosity and density for settling down saline water.

- Wash water: Mixing freshwater plays an important role here. If less amount of wash water is mixed into it dissolution of all salt content will not be possible. In the same way, if more wash water is mixed into crude oil separating water from crude will become a tough job to press. The optimum range for water is 4% to 8%

- Wash water pH value: with a change in the pH value higher or lower than 7, wash water conductivity of increases. So, it is necessary to maintain the wash water pH value at 7 for optimum efficiency of the desalter.

- Level of water-crude interface: This level should keep constant as per designed value as this affects the quantity of desalted crude extraction from desalter. if the Water-crude interface increase then oil extraction in the oil collector pipe will have some amount of water in it. while if the Water-crude interface decreases Oil will drain out with saline water and get wasted

- Pressure drop in mixing valve: A high-pressure drop operation results in the formation of a fine stable emulsion and better washing. however if the pressure drop is excessive, the emulsion might be difficult to break.

- Charge Rate: API gravity or specific gravity of crude should not differ more than 10% of the designed value. If the value is less than 10% crude will be lighter and foot on water because of which extraction of the salt content from crude oil will not be possible. and if the value is greater than 10% Crude will sink in water which makes the separation of crude from water very difficult.

- Demulsifing Chemicals: Nature of demulsifying agent effect how affectively water droplet will be separate from crude. The commonly used demulsifying chemical is Ethylene oxide-Propylene oxide copolymer.

Desalter Treatment challenges

Desalting treatment find some challenges during its processing and separation are as follows:

- Heavy Crude processing can lead to poor emulsion resolution

- High quantity of Amines/Ammonia content in wash water causing emulsion and increased salt deposition in-unit overheads

- An increase in water recycle can cause cycling up of amines/ammonia

- Presence of trapped amines in crude oil due to excessive usage in oil exploration, leading to the emulsion in desalter & fouling in the downstream unit.

- Crude Metals Content, Organic Calcium (Calcium Naphthenate), Calcium Carbonate, Iron Naphthenate, and Iron Sulfide

- A high amount of Solids, for example, Silica & Iron sulfate (FeS) causing solids-stabilized emulsion inside desalter and fouling of heat exchangers downstream of the desalters, especially in synthetic/tar sand crudes

- Potential crude blend incompatibility causing desalter emulsion issues

- Water/Solids Slugs causing frequent upsets that shut down the power grids due to excessive grid amperage

- Fouling of the Desalter Brine circuit due to incremental solids

- High H2S levels in the brine

Difference between Desalting and Desalination

Difference between Desalter and Desalination

| SL. NO. | Factors | Desalting | Desalination |

|---|---|---|---|

| 01 | Purpose | Removes salt content from crude oil | Remove mineral components from saline water |

| 02 | Process | Demulsification | Generally Reverse osmosis |

| 03 | Working method | Density and visocity difference to Separate salt content from crude | Pressure difference to Separate minral from saline |

| 04 | Processing Temperature | 120ºC to 140ºC | Not required to heat until thermal energy is not applied for processing |

| 05 | Hazard | Drained out water can be recycled to non-hazardous b product | By product is highly hazardous to environment |

| 06 | Cost | Comparatively low | Comparatively high |

Conclusion

Desalting is a method to extract salt content and other oleophobic impurities from crude oil and the equipment used for this purpose is called desalter. Desalter and Desalting process can be summarised as:

- Desalter is important to extract impurities that corrode equipment and piping.

- Because of desalting flowability of crude increases because of the absence of impurities from crude.

- Desalting tends to less maintenance for equipment and piping systems.

- There are mainly 03 types of impurities present in Crude: a. Salt b. Sendiments c. Water

- There is 03 method of desalting: Mechanical, Chemical, and electrical.

- There are two types of Desalter according to process: Single-stage desalter and two-stage desalter.

- Mixing of water to crude is 4%-8% for efficient working of desalter.

- Crude is preheated up to 120ºC to 140ºC before adding water for making the mixture conductive.

- Desalting is done with help of the generation of high voltage from the transformer to the oil-water mixture.

- Desalination and Desalting are two quite different processes.