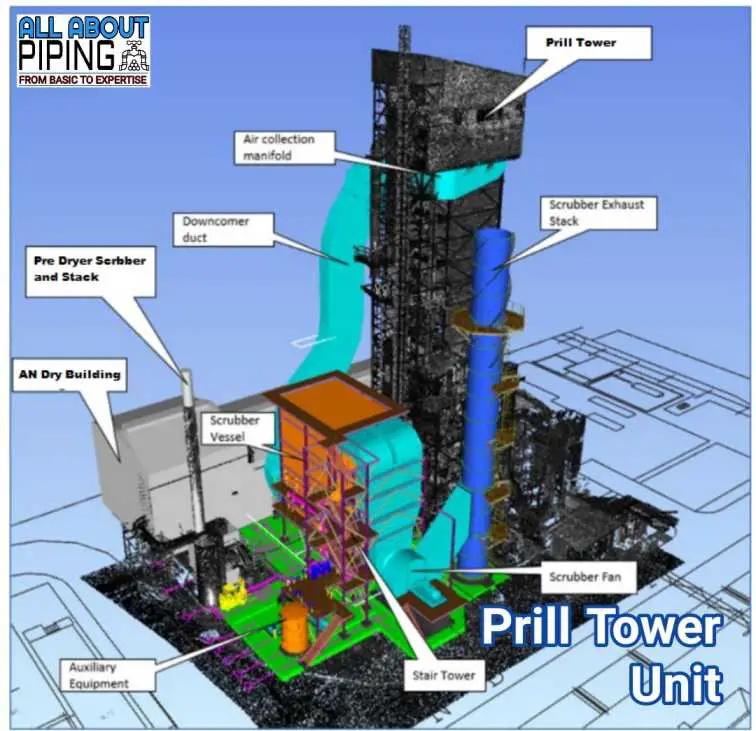

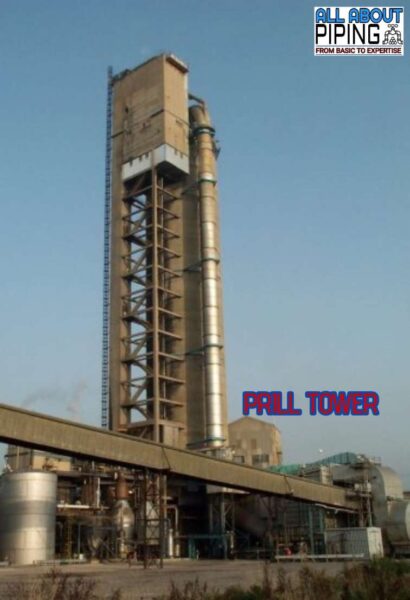

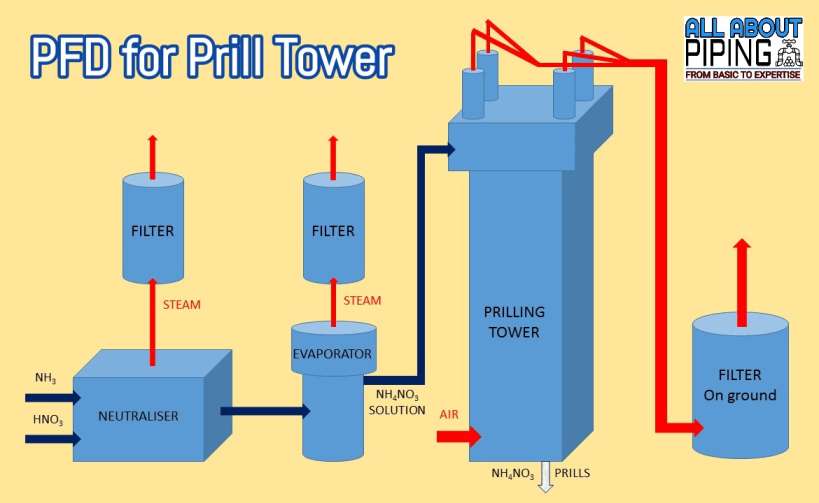

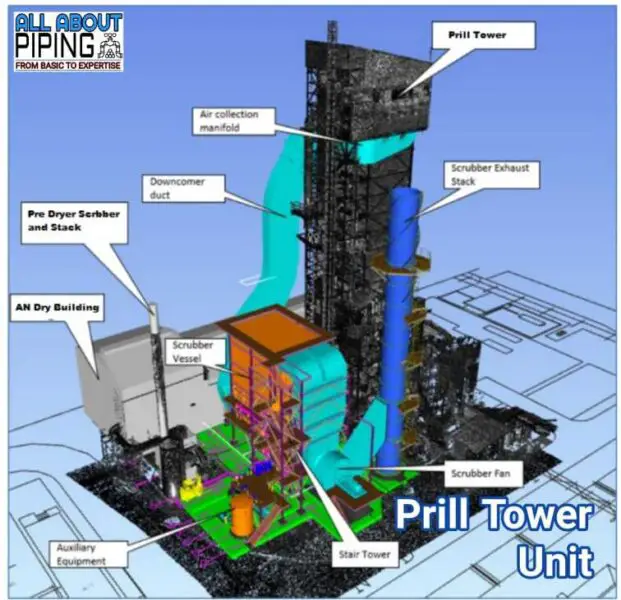

Fertilizer is often sold as small pellets known as ‘prills’, formed by pumping hot liquid fertilizer slurry through spray heads at the top of a tall tower. Air is sucked in at the bottom, heated, and blown up the center shaft of the tower. As the fertilizer falls down the shaft, it dries and solidifies to form prills, which are directed by a conveyor from a collection hopper at the tower base to the packing and shipping located in a building away from the Prill Tower. Fertilizers are frequently based on ammonium nitrate or urea. The same prilling technique can be used for either of these processes.

Table of Contents

What is Prill Tower?

A Prill tower is a key equipment within a fertilizer plant designed for the production of solid fertilizer in a granular form, known as prills. These towers are massive structures, often towering several stories high, characterized by their intricate network of pipes, vessels, and control systems. Prill towers are integral to the process of converting liquid fertilizers into solid particles, facilitating easier handling, transportation, and application in the field.

More Resources: Type of Control valve: XV, PV, TV, LV, HV, brief on the working and selection

How Prill tower work?

The processing and working of a prill tower for the formation of Ammonium nitrate prill is a 05 step process that can be understood with the following explanations:

- Feed Solution Preparation: The process begins with the preparation of a feed solution, which typically consists of water and dissolved nutrients. This solution may also include additives to improve handling characteristics or enhance nutrient uptake by crops.

The prepared feed solution is then introduced into the Prill tower. Inside the tower, the solution encounters controlled conditions that facilitate its transformation into solid particles. - Evaporation: Once inside the tower, the feed solution is subjected to heat, causing the water component to evaporate. This evaporation process concentrates the nutrient content in the solution, laying the groundwork for the formation of solid prills.

- Crystallization: As the water evaporates, the concentration of nutrients in the solution increases. At a certain point, the solution becomes supersaturated, leading to the spontaneous formation of solid crystals. These crystals serve as the nuclei around which the prills will form.

- Prill Formation: The supersaturated solution containing the solid crystals is then sprayed or dripped onto a surface within the tower. As the droplets travel downward, they come into contact with cooler air or surfaces, promoting further crystallization and solidification. This process results in the formation of spherical or irregularly shaped prills.

- Cooling, Hardening, and Collection: After formation, the newly formed prills continue to descend through the tower. Along the way, they are exposed to cooler air or cooling surfaces, which facilitates their hardening and solidification. This step is crucial for ensuring the prills maintain their structural integrity and do not break apart during handling or transportation.

Once fully hardened, the prills are collected at the bottom of the Prill tower. They may undergo additional processing steps, such as sizing, screening, or coating, to achieve the desired characteristics before being packaged for distribution and use in agricultural settings.

In summary, a Prill tower operates on the principles of evaporation, crystallization, and solidification to convert liquid fertilizers into solid prills. By carefully controlling temperature, humidity, and other parameters within the tower, fertilizer manufacturers can produce high-quality prills with consistent nutrient content and physical properties, ultimately contributing to the efficiency and effectiveness of modern agricultural practices.

More to Read: Falling film evaporator: Design, Working, Features and Application

Design methodology of Prill Tower

Designing a prill tower required a detailed approach towards process consideration of various factors like the properties of the feed solution, required prill characteristics, production capacity, and other safety and efficiency considerations. Here is a general methodology for creating a basis for designing a prill tower:

- Prill Tower Requirements: When designing a Prill tower, the first step is to decide what kind of fertilizer it will make. This involves figuring out the ingredients needed, like which nutrients it will have and how much of each.

It’s also important to determine the size, shape, and nutrient content of the small particles called prills that the tower will produce. Additionally, we need to consider how much fertilizer the tower should make while keeping the environment safe. - Material and Process Compatibility: Designing a Prill tower involves carefully considering the properties of the liquid fertilizer solution. This includes things like how thick it is, how heavy it is, and what it’s made of. Once we understand these properties, we can choose the right materials to build the tower.

Since fertilizers are harsh and the tower works in tough conditions, we need materials that can handle that. It’s crucial to make sure these materials work well with the fertilizers and the processes used in the tower, like heating and cooling. This ensures the tower lasts a long time and works efficiently. - Heat and Mass Transfer Analysis: Understanding the properties of the liquid fertilizer solution is essential for designing the tower. After that, we can pick the right materials for construction. Making sure these materials work well with processes like heating and cooling is important for the tower to work efficiently and last a long time.

- Equipment Sizing and Selection: To make sure the Prill tower works properly, we need the right equipment like heat exchangers, pumps, and control valves. We choose the size of this equipment based on how much fertilizer is required to produce and its maintenance ease.

- Safety and Environmental Considerations: Safety is the most important thing when designing a Prill tower. This means adding safety features like valves to release pressure and systems to shut down the tower in emergencies. Good ventilation is also crucial to prevent accidents. We also need to make sure the tower doesn’t harm the environment by controlling emissions. Following safety rules is a must to keep everything safe and in line with regulations.

By following this methodology, engineers can develop a Prill tower design that meets the specific requirements of fertilizer production, delivers high-quality prills, and operates safely and efficiently.

More to Read: 1G, 2G, 3G Bioethanol: What are different Bioethanol generation technologies?

Differences between Prilling and Granulation

Prilling and granulation are both methods used in fertilizer production, but they differ in their processes and the characteristics of the resulting products.

Prilling involves the formation of small spherical particles, known as prills, from a molten or liquid feedstock. This process typically utilizes a prill tower where the feed solution is sprayed or dripped onto a surface, allowing the droplets to solidify as they travel downward. Prills produced through prilling tend to be uniform in size and shape, with smooth surfaces. This method is often used for producing urea and ammonium nitrate fertilizers.

Granulation, on the other hand, involves the formation of larger granules by agglomerating smaller particles together. This process typically involves mixing solid particles with a binder solution to form granules of the desired size and shape. Granules produced through granulation can vary in size, shape, and surface texture depending on the specific formulation and processing conditions. This method is commonly used for producing complex fertilizers containing multiple nutrients, as well as specialty fertilizers with specific properties.

In summary, the main differences between prilling and granulation lie in the size and shape of the resulting particles, as well as the processes used to produce them. Prilling produces small, spherical prills through solidification of liquid feedstock, while granulation produces larger granules through agglomeration of solid particles with a binder solution.

Conclusion

A Prill tower operates on evaporation, crystallization, and solidification principles to convert liquid fertilizers into solid prills. By carefully controlling temperature, humidity, and other parameters within the tower, fertilizer manufacturers can produce high-quality prills with consistent nutrient content and physical properties, ultimately contributing to the efficiency and effectiveness of modern agricultural practices