Bioethanol generation is a process of producing a type of biofuel called ethanol from organic materials, such as corn, sugarcane, and other crops. Bioethanol is an important renewable fuel that can be used as a substitute for gasoline in vehicles, as a cleaner-burning fuel for heating and cooking, and as an additive in gasoline to increase its octane rating and reduce harmful emissions.

Efforts are being made to improve the efficiency and sustainability of bioethanol production, such as using waste materials or non-food crops as feedstocks and utilizing new technologies to reduce energy and water use in the production process.

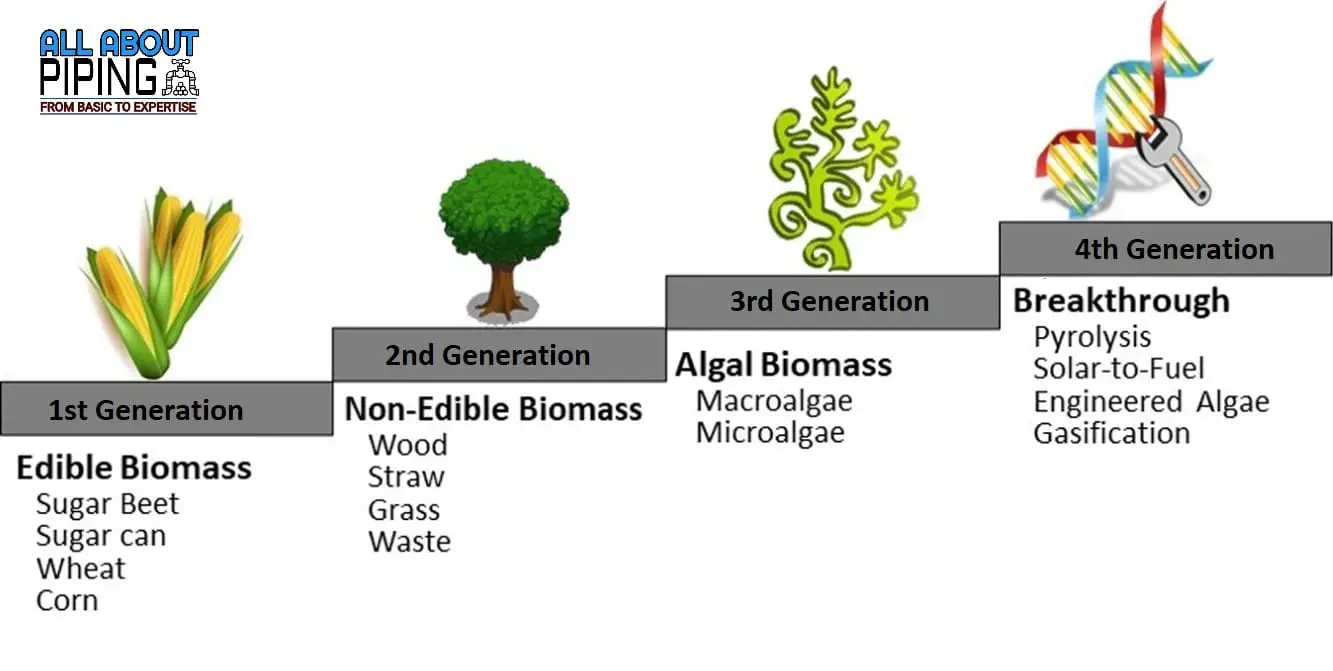

Different technologies evolved for the generation of bioethanol. These are named 1G, 2G, or 3G bioethanol. In this article, we will learn about bioethanol and its generation technologies.

Featured Article: Type and Selection of Hydraulic Oil

Table of Contents

What is Bioethanol?

Ethanol or ethyl alcohol( C2H5OH) is a clear colourless liquid, it’s biodegradable, low in toxins, and causes little environmental pollution if spilled. Ethanol burns to produce carbon dioxide and water. Ethanol is a high-octane energy and has replaced lead as an octane enhancer in petrol.

Bioethanol is a biofuel produced from plant material, mainly corn, sugarcane, or wheat. It is an alternative fuel source to gasoline and can be used as fuel for vehicles or in the production of other chemicals. Bioethanol is renewable and has lower greenhouse gas emissions compared to gasoline, making it an environmentally friendly alternative.

Bioethanol is used as a fuel for heating, transportation, and cooking, and can be blended with gasoline to reduce greenhouse gas emissions and dependence on fossil fuels. Bioethanol is a clean-burning, renewable alternative to gasoline and has a lower carbon footprint compared to fossil fuels.

By blending ethanol with gasoline we can also oxygenate the energy admixture so it burns more fully and reduces contaminating emigrations.

Types of Bioethanol generation

For the production of bioethanol, we have technologies of 04 generations. All of these technologies have different feedstock and different methods of bioethanol generation.

Currently, industrial bioethanol production is divided into three generations based on the types of feedstock used for the production of bioethanol generation. In general, the process involved in all types of Bioethanol generation are:

- Pretreatment

- Hydrolysis

- Fermentation

- Dehydration

Currently, there are 03 technologies available to us that are proven and research is being carried out for fourth-generation bioethanol generation:

- 1st Generation Bioethanol: In this technology, edible feedstocks are being used for bioethanol production.

- 2nd generation bioethanol: This is defined as bioethanol produced from a wide array of different feedstock, ranging from lignocellulosic feedstocks like bagasse wastes, rice wastes, corn wastes, and spent grains to municipal solid wastes.

- 3rd generation bioethanol: This is related to algae biomass which is used for fermentation. Here hydrogen-rich gases as used as feedstock.

- 4th generation bioethanol: Fourth-generation biofuels are the amalgamation of genomically prepared microorganisms and genetically engineered feedstock. Cyanobacteria are engineered to increase the oil yield and are used for the efficient production of bioenergy.

More Resources: PSV testing procedure: Popping test methods and PSV calibration (with PDF)

Why Bioethanol is Important?

Bioethanol is important because of the many advantages of bioethanol as fuel. Some of the important benefits are as below:

- Reduces dependency on oil imports: For a country like India, which imports most of the required oil. Production and consumption reduce the reliance on fossil fuels. It creates energy security and empowers a country having limited access to natural oil resources.

- Cleaner Environment: Exhaust from Bioethanol blended with gasoline are cleaner in nature because of their ability to reduce the overall carbon footprint and this also helps to reduce “Greenhouse gas” emissions by reducing agricultural waste.

- Renewable energy source: Bioethanol is produced using plant-based wastes (1G & 2G) or from waste gas of Refinery (3G). Its generation can be continuous as all plants/crops can be regrown which makes this a renewable energy source.

- Financial benefits for farmers: In the early days, Agricultural residues and wastes are being burnt by farmers and their handling was also an issue for them. Now with bioethanol generation technologies, farmers get the cost of their waste products too.

- Compatibility with existing infrastructure: Bioethanol can be easily blended with gasoline, which makes it relatively easy to incorporate into the existing transportation infrastructure, without requiring significant changes to vehicles or fuel distribution systems.

Overall, bioethanol is an important alternative fuel source due to its environmental and economic benefits, and its compatibility with existing infrastructure.

More Resources: Difference between WPS and PQR (WPS vs PQR)

Innovations in Bioethanol generation

In recent years, there have been several advancements in the technology for producing bioethanol. Some of these include:

- Improving the efficiency of enzymes used in the fermentation process.

- Using new feedstocks, such as algae, for bioethanol production.

- Developing advanced processing methods, such as hydrolysis, to break down complex carbohydrates into simpler sugars.

- Using genetically modified organisms (GMOs) to improve the yield and efficiency of the fermentation process.

- Implementing advanced distillation and purification methods to increase the purity of the bioethanol produced.

These innovations have led to a significant increase in the efficiency and cost-effectiveness of bioethanol production, making it a more attractive alternative to traditional fossil fuels. Another Innovation in Bioethanol production in this field has been as follows:

- An Indian company has filed a patent for loop reactor technology.

- It is a long, serpentine tubular reactor, in which fermentable sugars are converted to ethanol with the help of brewer’s yeast.

- This sparked an idea to develop reactive pipeline technology, wherein the pipeline connects the sugar factories where the ethanol is produced to the blending depot at the closest oil manufacturing companies.

- Reactive pipeline technology is poised to be a game-changer for sugar factories and grain-based distilleries since uninterrupted raw material supply is a major challenge.

Ethanol Blending and benefits of Bioethanol blending

Ethanol blending is the process of mixing ethanol with gasoline to create a fuel blend that can be used in spark-ignition engines. The most common ethanol blend is E10, which contains 10% ethanol and 90% gasoline. Higher ethanol blends, such as E15 and E85, are also available, but their use is more limited due to the availability of compatible vehicles and infrastructure.

Benefits of bioethanol blending

- Reduced greenhouse gas emissions: Bioethanol is a renewable fuel made from plant-based materials, such as corn, sugarcane, and switchgrass. When blended with gasoline, it can reduce greenhouse gas emissions by up to 43% compared to pure gasoline.

- Improved air quality: Ethanol blends burn cleaner than pure gasoline, reducing emissions of harmful pollutants such as carbon monoxide and particulate matter.

- Energy security: By using domestically produced bioethanol, countries can reduce their dependence on foreign oil and improve their energy security.

- Economic benefits: Bioethanol production creates jobs in agriculture and biofuel production, and can provide new revenue streams for farmers and rural communities.

- Higher octane rating: Ethanol has a higher octane rating than gasoline, which can improve engine performance and efficiency.

- Lower cost: Depending on the price of ethanol and gasoline, bioethanol blends can be less expensive than pure gasoline, providing cost savings for consumers.

Disadvantages of Bioethanol

While bioethanol has several advantages as a renewable and cleaner-burning fuel, it also has some potential disadvantages, including:

- Land use: The production of bioethanol requires a large amount of land to grow crops, which can compete with food production, biodiversity conservation, and other land uses.

- Food prices: The use of food crops, such as corn and sugarcane, as feedstocks for bioethanol production can lead to higher food prices and food insecurity, especially in developing countries.

- Energy and water use: The production of bioethanol requires a significant amount of energy and water, which can increase the overall environmental impact of the fuel.

- Fossil fuel use: The production of bioethanol often relies on fossil fuels, such as natural gas and coal, for energy, which can undermine the environmental benefits of the fuel.

- Ethanol compatibility with some vehicles: Some older vehicles and small engines are not designed to run on fuel blends containing high levels of ethanol, which can limit the use of bioethanol as a fuel.

- Limited availability: The availability of bioethanol as a fuel is still limited, particularly in regions with limited infrastructure for distribution and storage.

- Lifecycle emissions: Although bioethanol can reduce greenhouse gas emissions compared to fossil fuels, the overall lifecycle emissions, including emissions from production, transportation, and land use changes, can vary depending on the specific feedstocks and production methods used.

It is important to carefully consider the potential environmental and social impacts of bioethanol production and use and to explore ways to improve the sustainability of the industry, such as by using non-food feedstocks or increasing the efficiency of production processes.

Most Common Ethanol blending types

The most common ethanol blends used in transportation fuel are:

- E10: This blend contains 10% ethanol and 90% gasoline. It is approved for use in all conventional gasoline-powered vehicles and is widely available at gas stations throughout the country.

- E15: This blend contains 15% ethanol and 85% gasoline. It is approved for use in vehicles model year 2001 and newer, but not in motorcycles, boats, or small engines. E15 is less widely available than E10 but is still sold in many states.

- E85: This blend contains up to 85% ethanol and is designed for use in flexible fuel vehicles (FFVs). FFVs are capable of running on any blend of gasoline and ethanol up to E85. E85 is less widely available than E10 or E15 and is mostly sold in the Midwest and other areas with high concentrations of FFVs.

It’s worth noting that ethanol blends above E10 (i.e., E15 and E85) are not approved for use in all gasoline-powered vehicles, and using them in non-FFVs or non-approved vehicles can cause engine damage and void the vehicle warranty. It’s important to check the owner’s manual or consult with the vehicle manufacturer before using any ethanol blend higher than E10.

Can Ethanol Replace fossil fuels?

Ethanol is a renewable fuel source that can be produced from agricultural crops such as corn, sugarcane, and wheat. It is often blended with gasoline to produce a fuel that can be used in traditional combustion engines. While ethanol has the potential to partially replace fossil fuels, there are several factors to consider.

Firstly, ethanol production requires significant amounts of land, water, and energy. This can lead to environmental concerns such as deforestation, soil erosion, and water pollution. In addition, the production of ethanol can result in greenhouse gas emissions, particularly if the crops used to produce it are grown using fossil fuel-based fertilizers and pesticides.

Secondly, ethanol has a lower energy density compared to gasoline, which means that it produces less energy per unit of volume. This can result in decreased fuel efficiency and range in vehicles that run on ethanol-blended fuels.

Third, there are also concerns about the impact of ethanol production on food prices and availability, as crops that are used to produce ethanol are also used for food production.

Overall, while ethanol can be used as a partial replacement for fossil fuels, it is unlikely to fully replace them due to the various limitations and challenges associated with its production and use. It may be more effective to explore a range of alternative energy sources and technologies to reduce our reliance on fossil fuels.

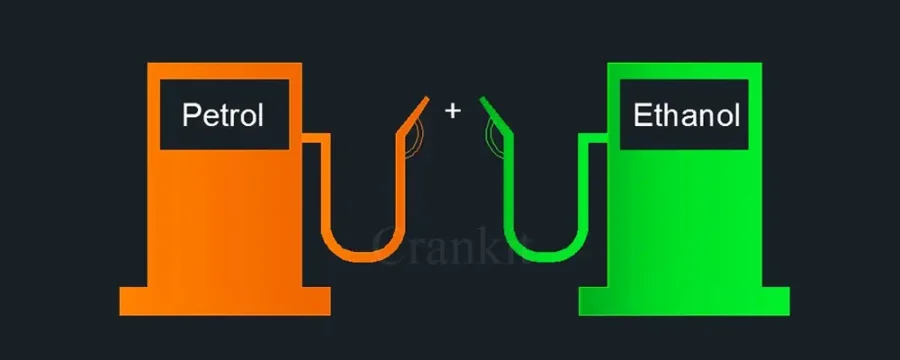

2G Bioethanol process description

2G bioethanol production refers to the production of second-generation bioethanol from lignocellulosic feedstocks such as agricultural residues, forestry residues, and dedicated energy crops. The process typically involves the following steps:

- Feedstock preparation: The feedstock is cleaned and chopped into small pieces to increase its surface area for easier processing.

- Pretreatment: The feedstock is subjected to physical or chemical pretreatment to break down the lignocellulosic structure, making the sugars in the material more accessible to enzymes.

- Hydrolysis: The pretreated feedstock is then hydrolyzed, which involves adding enzymes to break down the cellulose and hemicellulose into sugars, mainly glucose, and xylose.

- Fermentation: The hydrolysate is then fermented by yeast or other microorganisms to convert the sugars into ethanol.

- Distillation: The fermented liquid is then distilled to separate the ethanol from the water and other impurities.

- Purification: The distillate is then subjected to purification to remove any remaining impurities and increase its ethanol content.

- Drying: The purified bioethanol is then dried to reach the desired moisture content.

The resulting bioethanol can be used as a fuel or blended with gasoline to reduce greenhouse gas emissions and dependence on fossil fuels.

Technology selection criteria for 2G bioethanol

The selection criteria for 2G bioethanol production technology can include the following:

- Feedstock availability and cost: The technology should be able to use a wide range of feedstocks, such as agricultural waste, wood chips, and energy crops, and should be economically viable.

- Conversion efficiency: The technology should be able to convert the feedstock into bioethanol with a high yield efficiently.

- Energy efficiency: The technology should be energy efficient, requiring minimal energy inputs to produce bioethanol.

- Environmental impact: The technology should have a minimal environmental impact, such as producing low greenhouse gas emissions and minimizing waste.

- Scalability: The technology should be scalable to meet the growing demand for bioethanol.

- Product quality: The technology should produce bioethanol with consistent quality, meeting relevant industry standards.

- Cost: The technology should have a reasonable cost of production and should be economically viable in the long term.

Technological challenges of 2G bioethanol

The production of 2G bioethanol, also known as second-generation bioethanol, presents several technological challenges. Some of the major challenges include:

- Feedstock availability: One of the main challenges is sourcing the feedstock for 2G bioethanol production. The feedstock for 2G bioethanol is typically lignocellulosic biomass, which is not as readily available as sugarcane or corn, which are commonly used for 1G bioethanol production.

- Pretreatment: Lignocellulosic biomass is more complex than sugar-based feedstocks, and requires more extensive pretreatment to break down the complex structure of the biomass into simple sugars that can be fermented into ethanol.

- Enzyme production: Pretreatment also requires the use of specific enzymes to break down the lignocellulosic material into simple sugars. The cost of producing these enzymes is still relatively high, and research is ongoing to develop more cost-effective methods of producing these enzymes.

- Fermentation: The fermentation process for 2G bioethanol is also more complex than that for 1G bioethanol. This is due to the presence of inhibitors in lignocellulosic biomass that can interfere with the fermentation process.

- Separation and purification: The separation and purification of the ethanol produced from lignocellulosic feedstocks are also more complex and require more energy compared to 1G bioethanol.

Despite these challenges, the development of 2G bioethanol is seen as a promising alternative to first-generation bioethanol and petroleum-based fuels, due to its potential to reduce greenhouse gas emissions, increase energy security, and promote rural development.

3G Ethanol or third generation bioethanol

The third generation or 3G bioethanol is produced when algae are used as the feedstock for ethanol production. Algae bioethanol is gaining popularity because of its high carbohydrate content and absence of lignin.

With this kind of feedstock the cost of pretreatment is expected to reduce as the complex lignin removal process is not needed anymore. 3G bioethanol production is a process that uses hydrogen-rich gases from refineries or Steel manufacturing plants. This process involves several key steps, including:

- PSA off-gas Feeding: The hydrogen-rich PSA off-gas from the hydrogen generation unit of refineries using a compressor fed in the system for fermentation where carbon-hungry microbes are present for further processing.

- Fermentation with Microalgae: The hydrogen-rich PSA off-gas is fermented using microalgae to produce ethanol and carbon dioxide. This process is carefully controlled with suitable parameters of nutrient addition to maximize the yield of ethanol.

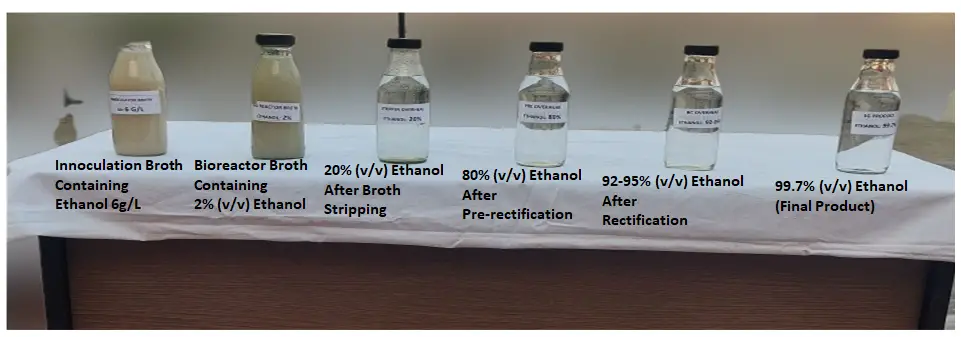

- Broth Stripping: Fermented solution is stripped in the broth stripper column for the processing of the 3G bioethanol production process which is then transferred to the falling film evaporator for further purification.

- Distillation: The stripped broth solution is then processed through a distillation column to separate the ethanol from the other components, such as water.

- Purification of Distilled Bioethanol: The distillate is purified using a pre-rectifier and rectifier column to attain maximum ethanol purity.

- Drying or Water Removal from Bioethanol: Even after purification some amount of water is present which needs to be removed before sending it to market. The purified ethanol is then dried to remove any remaining water, resulting in a high-purity (Approx. 99.6%) bioethanol that can be used as a fuel.

The 3G bioethanol production process is a cost-effective and environmentally friendly alternative to traditional fossil fuels. By using renewable feedstocks and reducing greenhouse gas emissions, this process helps to promote energy independence and reduce the impact of human activities on the environment.

Species of algae that can be used as per obtained results from research are as follows:

| SL. NO. | Algae | Bioethanol yield (%) |

|---|---|---|

| 1 | Nannochloropsis Oculata | 3.68 |

| 2 | Tetraselmis suecica | 7.26 |

| 3 | Scenedesmus dimorphus | 49.7 |

| 4 | Porphyridium cruemtum (seawater) | 65.4 |

| 5 | Porphyridium cruemtum (fresh water) | 70.3 |

| 6 | Padina Tetrastromatica | 16.1 |

Technological challenges of 3G bioethanol production

There are several technological challenges in the production of 3G (Third Generation) bioethanol:

- Hydrogen-rich feed gas: Sufficient supply of hydrogen-rich gas must be required for the production of 3G bioethanol.

- Chemical composition for Nutrient Solution: Effective and efficient nutrition feeding is a must to grow microalgae during fermentation. The parameters and ratio of each chemical component are very important for the proper growth of microalgae to produce bioethanol in the 3G bioethanol production process.

- Enzyme production: Cost-effective and scalable production of enzymes with the help of carbon-hungry bacteria for hydrolysis is a challenge as high-quality enzymes are essential for the efficient conversion of feed gas into ethanol-containing broth solution.

- During Fermentation: Microbial strains that can efficiently ferment with the addition of nutrients in proper ratio and parameters.

- Product separation and purification: Effective and efficient product separation and purification methods are needed to obtain high-quality bioethanol with low impurities.

- Integration with existing infrastructure: Integration with the existing processing plant for ethanol production and distribution is a challenge, as the processes and feed gas used in 3G bioethanol production are different from the traditional bioethanol production processes.

Conclusion

Bioethanol is considered the most important renewable fuel. For developing countries, approximate energy demand increases by 7% from year to year. Here Bioethanol provides a sustainable source of energy.

With 03 generations of bioethanol generation technologies we have. Bioethanol can be the fuel of the future which helps to Reduce green GHG, Improve air quality, provide energy security, and lower costs.