Pipe beveling is an integral process across diverse industries to modify the edges or ends of pipes, creating specific angles or surface configurations. It holds important significance in facilitating efficient and reliable pipe connection joints, enhancing welding or joining procedures, and ensuring overall pipework integrity and functionality.

By beveling the pipe ends, efficient fit-up can be achieved, which enables and improves weld penetration and hence, enhances the flow characteristics of fluids or gases conveyed through the pipes. Understanding the core principles of pipe beveling is important for doing secure and effective connections of piping systems in construction projects.

More Resources: What is Orbital Welding? Benefits, Factor affecting, Application, Advantages, Disadvantages

Table of Contents

What is beveling?

Beveling is the process of creating an angled cut or bevelled edge on the perimeter of a material. It is commonly employed in metalwork to achieve a polished and finished appearance to facilitate joining two pieces together at an angle.

To achieve a bevel, various tools are used, including bevel gauges, grinding machines, or specialized beveling machines. The specific angle and width of the bevel can vary depending on the desired outcome and the material being worked on. Typically, bevel angles of 45 and 30 degrees are common, although other angles can be utilized depending on the application.

How to bevel a pipe?

Safety precautions are much important during the beveling of a pipe. For the operation of beveling you will need the following tools:

- Pipe beveling machine or grinder machine

- Safety goggles

- Gloves

- Deburring tool or file

- Measuring tape or ruler

Here’s a step-by-step guide on how to bevel a pipe:

- Put on your safety goggles and gloves to protect yourself.

- Measure the length of the bevel you want on the pipe. Decide the angle and length of the bevel you desire. Common angles for pipe beveling are 30 degrees and 45 degrees.

- Secure the pipe in a vice or pipe clamps to keep it stable.

- If you have a pipe beveling machine, follow the instructions to set it up and adjust it to the desired angle and length. If you’re using a grinder with a beveling attachment, make sure the attachment is securely in place.

- Start the beveling process by using the beveling machine or grinder on the edge of the pipe. Move the machine or grinder along the edge of the pipe with gentle and consistent pressure. Keep the desired angle and length of the bevel in mind.

- Continue beveling until you have achieved the desired bevel on the edge of the pipe. Take your time and make sure the bevel is smooth and even.

- After beveling, check the pipe to ensure that the bevel is clean and doesn’t have any rough or jagged edges. Use a deburring tool or file to remove any burrs or sharp edges and make the edge smooth.

- Once you’re satisfied with the beveling and the pipe’s edge is smooth, clean off any debris or metal shavings from the pipe.

Remember, the beveling process may vary depending on the type and size of the pipe, as well as the tools you’re using. Always follow the instructions provided by the tool manufacturer.

More Resources: Welding Hazards and control measures with pdf

Types of Beveling

Commonly used in various industries for metalworking to enhance the appearance, functionality, or weldability of a component. The following are several common types of beveling:

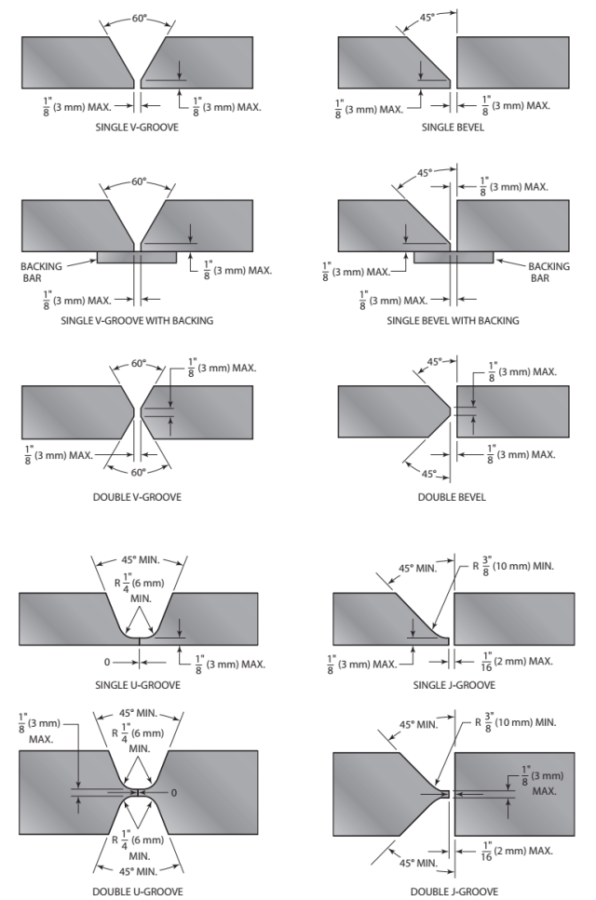

- Straight Bevel: This type of beveling involves machining the edge to create a straight angle or chamfer. It results in a straight line between two surfaces, usually at a designated angle like 45 degrees or 30 degrees.

- V-Bevel: A V-bevel creates a V-shaped groove or chamfer on the workpiece’s edge. It is often used in welding applications to prepare the edges of metal plates for joining in a V-groove weld.

- Double Bevel: Also known as a compound bevel, double beveling involves machining both sides of the workpiece edge to create a specific angle or chamfer. Woodworking and carpentry commonly utilize this type of beveling to create decorative edges or joints.

- J-Bevel: A J-bevel forms a J-shaped groove or chamfer on the edge of the workpiece. It is commonly employed in welding applications where deep penetration welds are required.

- Knife Edge Bevel: This type of beveling creates a thin and sharp edge on the workpiece. It finds applications in surgical instruments, razor blades, and cutting tools.

- Radiused Bevel: Radiused beveling involves machining the edge of the workpiece to create a rounded or curved chamfer. It is often used to improve safety, ergonomics, or aesthetics.

- Countersink: Although not strictly a bevel, a countersink is a conical-shaped recess created at the surface of a hole. It allows the head of a screw or bolt to sit flush with or below the workpiece’s surface, preventing interference or providing a smooth finish.

How to Choose between V Groove and J Groove?

When deciding between a V groove and a J groove for welding, there are a few factors to consider as follows:

| SL. No. | Factors | V groove | J groove |

|---|---|---|---|

| 01 | Joint Strength | Provides higher joint strength due to more surface area for welding. | Offers slightly lower joint strength compared to V groove welds. |

| 02 | Welding Position | Can be more challenging in tight or hard-to-reach areas. | Easier to access and weld due to the wider opening. |

| 03 | Material Thickness | Suitable for thicker materials, allowing deeper penetration. | Commonly used for thinner materials where deep penetration isn’t necessary. |

| 04 | Welding Procedure | Compatible with procedures like GMAW or FCAW, offering higher deposition rates. | Can be used effectively with various welding procedures, including GTAW. |

| 05 | Weld Appearance | More material removal and preparation are required, potentially increasing welding costs. | Provides a shallower groove, resulting in a smoother and more blended appearance. |

| 06 | Welding Cost | More material removal and preparation are required, potentially increasing welding costs. | More material removal and preparation are required, potentially increasing welding cost. |

How to choose the correct beveling method?

Selecting a correct beveling method involves considering various factors that impact the outcome of the strength of the joint. These factors include the material you’re working with, the desired bevel angle and width, the tools and equipment available to you, and the specific requirements of the material and thickness. The following factors are to be considered to choose the correct beveling method:

- Material: Each material, either Carbon steel, Alloy steel or stainless steel. All materials have their own characteristics that affect the beveling process. Factors like hardness, thickness, and brittleness should be taken into account when selecting a method. Some materials may respond well to manual beveling using hand tools, while others may require the power and precision of specialized machinery.

- Bevel angle and width: Consider the specific angle and width of the bevel you want to achieve. This will help you narrow down your options. For precise and consistent bevel angles, machine-based methods are a good choice. On the other hand, if you require flexibility to adjust the angle and width as you work, manual methods might be more suitable.

- Tools and equipment: Evaluate the tools and equipment you have access to. Are you equipped with specialized beveling machines, routers, or grinders? The availability and capabilities of your tools will influence your choice of beveling method.

- Project requirements: Consider the specific demands of your project. Factors such as the size and complexity of the workpiece, the level of precision required, the desired finish quality, and any time constraints will impact your decision. If you’re working on a large or intricate project, automated or machine-assisted methods might offer greater efficiency and consistency.

- Skill level and experience: Assess skills and experience with different beveling methods. Certain techniques may require more expertise and practice to achieve the desired results. Choose a method that matches your capabilities and comfort level. Alternatively, be open to learning and developing new skills if needed.

More Resources: Difference between WPS and PQR (WPS vs PQR)

When Butt weld is used?

Butt welding is a technique commonly used in piping when there is a need for a strong and leak-proof joint between two pipes. It involves joining the ends of two pipes by heating them and then applying pressure to fuse them together. Butt welding is typically used in the following situations:

- High-pressure and high-temperature applications: Butt welding is often used in piping systems that handle fluids or gases under high pressure or at elevated temperatures. It ensures a strong joint that can withstand the forces and maintain the integrity of the piping system.

- Seamless pipes: Butt welding is commonly used with seamless pipes, which are pipes without any welded seams. Seamless pipes are preferred in critical applications where leakage or failure could have serious consequences. Butt welding allows for a continuous and smooth joint, ensuring the pipe remains strong and leak-proof.

- Large-diameter pipes: Butt welding is an effective method for joining large-diameter pipes. It provides a strong and reliable joint that can handle the forces and pressures associated with larger pipes.

- Structural integrity: Butt welding offers excellent structural integrity to the joint. By eliminating the need for additional connectors like couplings or flanges, which can introduce potential weak points or leak paths, butt welding ensures a solid and reliable connection.

- Welding codes and standards: Butt welding is often specified by industry codes and standards for certain piping applications, particularly in industries like oil and gas, chemical, and power generation. These codes and standards ensure that the welded joints meet specific quality and strength requirements.

It’s important to note that butt welding requires skilled welders and proper welding procedures to ensure a successful and reliable joint. The parameters of the welding process, such as heat input, welding technique, and filler material, must be carefully controlled to achieve a strong and defect-free weld.

More Resouces: Heat Tracing in Piping: Types, Working, Use, Installation, Comparison (Steam Tracing vs Electrical Tracing)

Hazards of beveling and safety measures

To ensure safety during pipe beveling, it is essential to follow established safety procedures, utilize appropriate personal protective equipment (PPE), receive proper training, and comply with relevant safety guidelines and regulations. Conducting a thorough risk assessment prior to starting the work will help identify specific hazards and implement suitable safety measures.

A few hazards and their control measures during beveling is as tabulated below:

| SL. No. | Safety Hazards | Hazard Description | Safety Measures |

|---|---|---|---|

| 01 | Eye and face hazards | Flying debris, sparks, and chips during beveling | Wear safety goggles or a face shield |

| 02 | Hand and finger injuries | Risk from tools and machinery used for beveling | Use appropriate gloves to protect hands and fingers |

| 03 | Noise and vibration | High noise levels and vibrations from power tools | Wear hearing protection and anti-vibration gloves |

| 04 | Respiratory hazards | Airborne dust, fumes, or gases from beveling processes | Use respiratory protection (masks or respirators) when needed |

| 05 | Burns and thermal hazards | Burns from hot surfaces or contact with hot tools | The risk from tools and machinery used for beveling |

| 06 | Ergonomic hazards | Strains, sprains, or musculoskeletal disorders from repetitive tasks | Receive proper training, wear heat-resistant gloves, and be cautious of hot surfaces |

Difference between beveling and chamfering

Beveling and chamfering are two completely different processes used to modify the edges or ends of objects. While the terms are often used interchangeably, there is a narrow difference between them:

Beveling: Beveling involves the creation of an angled surface or edge on a material, typically at an angle other than 90 degrees. It is commonly done to remove sharp edges, facilitate welding or joining, improve aesthetics, or create a functional shape. Beveling can be performed on various materials such as metal, wood, glass, or plastic. The resulting surface from beveling is generally flat or slightly concave.

Chamfering: Chamfering, on the other hand, refers specifically to the process of creating a bevelled cut or surface at the intersection of two surfaces, often at a 45-degree angle. The purpose of chamfering is usually to remove sharp corners or edges, facilitate assembly, or enhance the appearance and safety of an object. Chamfering can be applied to materials like metal, wood, plastic, or stone. The resulting surface from chamfering is typically flat.

Conclusion

In conclusion, pipe beveling is an Important process with much importance across different industries and applications. Modifying the edges or ends of pipes enables a great fit-up and improved welding.

Implementing proper pipe beveling techniques is a must for ensuring secure and effective connections, contributing to the overall integrity and functionality of piping systems. Prioritizing precision and adherence to safety protocols during the beveling process is crucial to maximizing performance and longevity.

With its multitude of benefits, pipe beveling plays a pivotal role in achieving reliable and efficient piping solutions for industrial, commercial, and residential needs.