The vacuum Ejector System is one of the most important parts of the Vacuum distillation unit. It creates pressure always less than outlet pressure of vacuum column downcomer piping so that flow of fluid Vacuum column to Condenser and other types of equipment can be regularised.

PV=nRT (P: Pressure, V: Volume, n: no. of molecules, R: constant, T: Temperature).

From the above equation, it is easily co-relate that, Temperature directly depends on Pressure. So, to make those compounds separate from the crude. A less pressure system is required that makes it possible to distill compounds even with higher boiling points.

Decreasing the pressure near to vacuum is required to save extra resources that will be required to gain temperature in normal pressure conditions. In this article explaining “Vacuum Ejector System” you will gain a wide approach for the following:

- What are Vacuum Ejector systems and their types?

- Terminologies and Working Principle of Vacuum Ejector.

- Advantage and Application of Vacuum Ejector.

- Selection Requirement.

- Comparison between Vacuum Ejector and Vacuum Pump.

More to Read: Crude Oil desalter: Purpose, Working, Types, Parts, variables

Table of Contents

What is Vacuum Ejector System?

A vacuum is defined as a space that is completely empty from any type of matter. In practice, a vacuum is termed as a place in which Pressure is less than Atmospheric Pressure. Less pressurized condition of Vacuum leads to boil crude content at less temperature. This basic fundamental of science applicable to initiate all Vacuum distillation processes.

The Equipment that helps the piping system to attain pressure less than atmospheric pressure is called Vacuum Ejector. And a combination of multiple ejectors with multiple stages is termed a Vacuum Ejector System.

An Ejector is typically a pumping device that doesn’t have any moving part in it. A vacuum jet ejector uses either gas or any fluid as an impelling force.

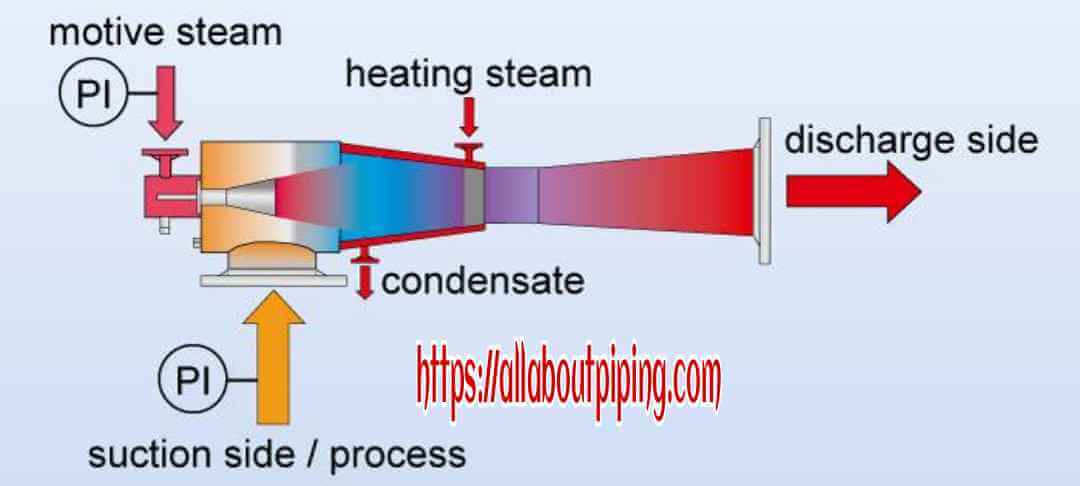

- If an ejector uses steam as its motive fluid then it is called a Vacuum Steam jet Ejector.

- If Ejector is using high pressurized compressed air then it will be called Air Vacuum Ejector.

- If Highly pressurized Water or some equivalent liquid is used as a motive force then the ejector package is called liquid jet Vacuum ejector.

Except for the type of motive force, the Vacuum ejector functions on the same working principle. In the case of air as a motive force, A compact ejector with air-saving regulation uses less compressed air in comparison with a traditional vacuum ejector system.

Feature Posts: Piping Supports: Types, Codes, Design, Selection, Working, Installation

Vacuum Ejector Component

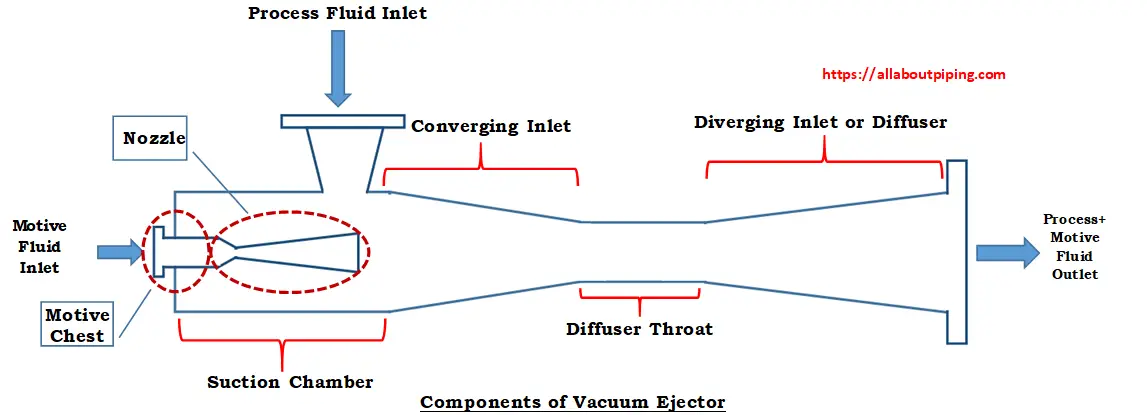

There is Mainly 06 sections of the Vacuum Ejector System As described below:

- Motive Chest: This is the chamber through which Motive fluid enters to Motive Nozzle

- Motive Nozzle: This is the nozzle of the vacuum ejector system that creates a venturi effect and develops a low-pressure region at its outlet.

- Suction Chamber: This is the part of the ejector package around which a low-pressure zone is developed.

- Converging Inlet: This is a portion of equipment after the Suction chamber where motive fluid and main process fluid got mixed.

- Diffuser Throat: This section of the ejector is after converging inlet having a constant diameter. Shockwaves are produced here which suddenly develops the Temperature and Pressure of the Entire Motive fluid and Process fluid mixture.

- Diverging Inlet or Diffuser: This is the place of the Vacuum ejector where velocity is converted to pressure.

Terminologies Related to vacuum Ejector

- Compression Ratio: This is the ratio between Discharge pressure of the Ejector outlet to Suction pressure of the Main process fluid

- Expansion Ratio: Ratio of motive pressure to Suction pressure.

- Flow Ratio: Ratio of Suction flow rate to motive flow rate.

- Sub-sonic Flow: Fluid flow with speed less than sound. Subsonic fluid has a Mach number less than 01.

- Super-sonic flow: Fluid flow with a speed higher than sound is called Supersonic flow. Mach number for this type of flow is greater than 01.

- Shock Waves: Wave produces high pressure and temperature in the medium.

- Motive Force: Pressure applied by Motive fluid.

- Mach number: It’s a dimensionless quantity that measures the flow velocity of a fluid with respect to the velocity of sound.

Vacuum Ejector Working Principle

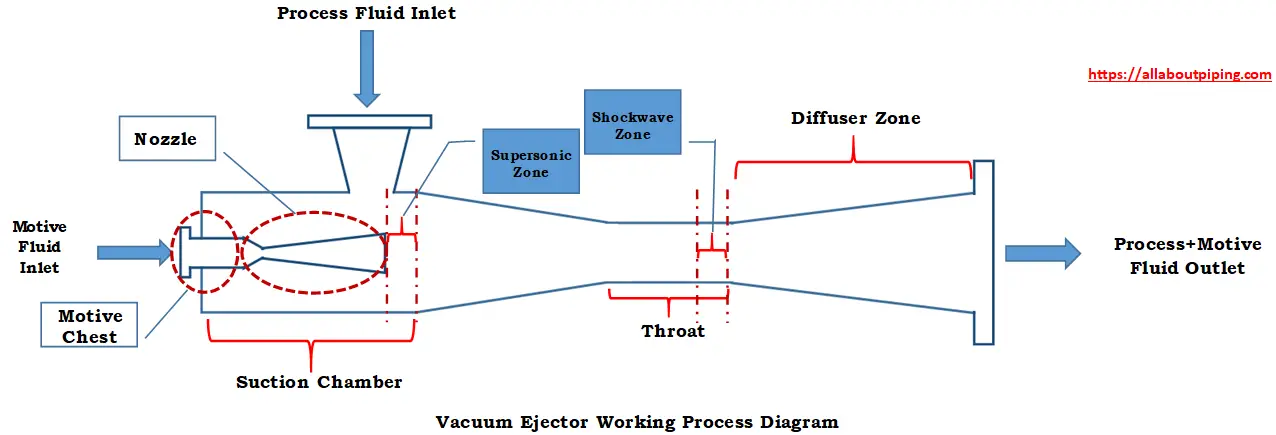

To understand how a vacuum ejector work first of you needs to mind these 03 concepts:

- In the case of Subsonic flow which has Mach number less than 01 when you decrease the area of outlet velocity will increase.

- For the case of supersonic flow that has a Mach number greater than 01 velocities will increase when you increase the area of the outlet nozzle.

- The nozzle used for the Ejector is a converging-diverging type nozzle.

Considering these 02 fundamentals of fluid flow. You can consider the following points towards understanding how a vacuum ejector work:

- When motive fluid is passing through the vacuum chest there is a sudden converging zone that increases the velocity of motive fluid up to a sonic fluid velocity.

- After this point when fluid already achieved Sonic velocity the nozzle with diverging outlet helps motive fluid to achieve supersonic velocity at the outlet of the nozzle.

- At the outlet of the nozzle speed of the motive, fluid is in supersonic speed.

- From general physics, We know that when the velocity of a fluid increase beyond supersonic velocity number of molecule in per unit area becomes very less that creates a vacuum zone as per Balance energy Equation or Bernoulli’s equation.

- Because of this vacuum zone, the Main process fluid is being sucked through its inlet nozzle in the suction chamber.

- In the further converging zone of the Vacuum ejector, Motive fluid with Super Sonic velocity and Sucked Process fluid got mixed and attend a common average velocity for both fluids in the suction chamber.

- After mixing, Fluid passes through the converging zone of the ejector.

- The Throat is designed such as when mixed fluid passes through this in a transonic phase, where supersonic velocity is converted into subsonic velocity and generate a shock wave.

- Because of this Transonic phase and shock wave, pressure, and temperature of the fluid at the throat portion increases suddenly.

- Because of this sudden increase in pressure throat portion act like a compressor without moving parts.

- After the throat portion, Subsonic fluid flow through a diverging zone (or diffuser zone) where the pressure of the fluid again increases as the velocity decrease in this area.

- And finally outlet mixed fluid will have enough pressure for transportation till condenser.

More to Read: Basics of Project Execution Plan for Piping Planning: A short Briefing

Advantages of Vacuum Ejector

- High vacuum level with a relatively small flow rate

- Maintenance-free and wear-free

- Low-cost, Low-weight, compact design

- Horizontal mounting position

- Comparatively High vacuum

- Minimal maintenance expenses

- Generally large dimensions and high weight

Application of Vacuum Ejector

A vacuum ejector is used in oil and gas industries to create a vacuum pressure to suck overhead gases from the Vacuum column. The applications of the vacuum ejector will vary according to the type of ejector modules.

- A vacuum ejector with Eco-nozzle technology produces a high suction rate. This reduces the consumption of air. This type of ejector used in packaging industries.

- It is used for air-tight workpieces

- Ejectors with a very low compression ratio for recovering harmful gases in industry.

Vacuum Ejector Selection Requirement

Here is a list of the typical data needed to select and size a steam ejector system:

- General process description: Location and elevation of ejector with service condition.

- Fluid composition and properties: While designing Ejector material composition at the inlet as well as the physical state having same importance towards the selection of ejector dimensions.

- Fluid flow rate, temperature, and pressure: According to fluid flow rate, temperature and operating pressure dimensions of ejector nozzle and diffuser dimensions are selected. So, specifying the range and normal expected values will the driving force that provides the flow.

- Evacuation requirements: During maintenance If the system must be evacuated within a certain time, providing the data related to system volume, initial conditions, and the maximum time allowed for evacuation is helps for operation and so for selection.

- Available steam pressure and quality: The value of minimum steam pressure for its different conditions like dry, saturated, or superheated.

- Ejector Material: Materials of construction for the three primary parts: steam nozzle, body, and venture diffuser.

- Condensing requirements: Multi-stage ejectors are more efficient with interstage condensers. So, the selection of an ejector depends on the type of condenser in use.

- Backpressure conditions: If the final stage will operate against backpressure, rather than discharging to the atmosphere, specify the pressure.

Vacuum Ejector vs Vacuum Pump

The major difference between Vacuum Ejectors and Vacuum Pumps are as follows:

Difference between vacuum ejector and vacuum pump

| SL. NO. | Coparison Factors | Vacumm Ejector | Vacuum Pump |

|---|---|---|---|

| 01 | Working Principle | Works on Bernoulli’s Principle | Works on mass displacement Principle |

| 02 | Components | No moving Components | Have moving components to generate pressure |

| 03 | Motive Source | High pressure fluid | Electricity |

| 04 | Durablity | Highly Durable and no wear and tear as no moving parts are present | Comparativly less life span |

| 05 | Maintenance | Very Low or No maintenance required | Time to time maintenance required for efficient working |

| 06 | Design factors | Simple design, Comparatively more weight and not compact in Size | Complex design, Comparatively Low weight and compact size |

| 07 | Vacuum Level | Comparatively Low vacuum level can be achieved | High vacuum level upto -0.98 bar can be achieved |

| 08 | Mounting Position | Always Horizontal | Any position |

| 09 | Energy Consuption | Very Less energy consuption compare to output Values | Comparatively high energy consuming compare to output values |

| 10 | Cost | Low | High |

Conclusion

The purpose of a Vacuum Ejector is not as the name suggests. Instead, this device is used to create pressure in the fluid.

- Vacuum Ejector work on the principle of Bernoulli’s equation.

- This uses Supersonic flow to create a vacuum for the suction of process fluid.

- A vacuum Ejector nothing but a compressor without moving parts.

- Because of the absence of moving parts, It is Wear and Tear-free and requires very little maintenance.

- This generates a high vacuum level with respectively low fluid flow rate.