There are multiple types of steam trap exist in the market. Each type of steam trap has different capabilities, processing functions, advantages, and disadvantages. But in all of these, A steam trap’s most important job is to quickly discharge condensate that has formed in the steam distribution line.

Steam traps are classified into different categories based on their construction and operational principles. In this article we will provide you detailed information about:

- Different types of Steam trap and their working principle.

- Advantages and disadvantages of each type of Steam trap.

Table of Contents

Types of Steam Trap

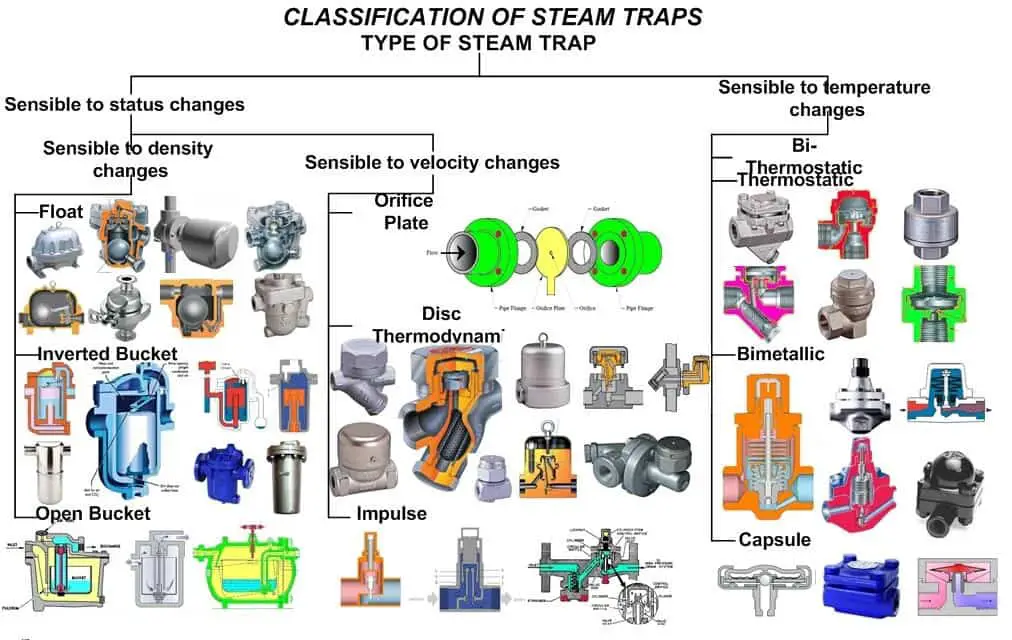

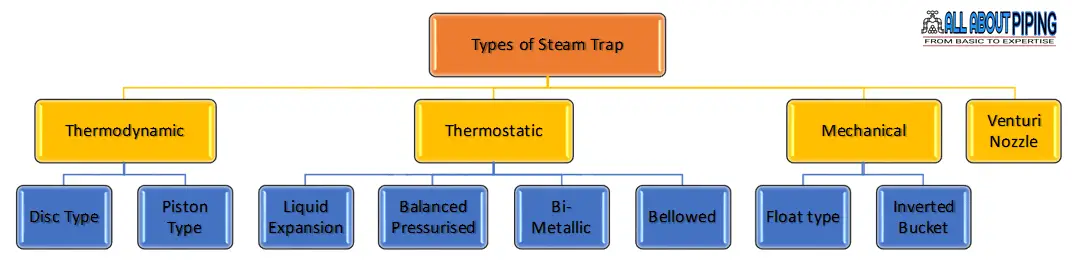

According to the functional nature of the steam trap, each steam trap falls into one of these 04 categories, and under each category types of steam trap is as follows:

- Thermodynamic Steam trap

- Disc type steam trap

- Piston type steam trap

- Mechanical Steam Trap

- Float type

- Inverted bucket

- Thermostatic steam trap

- Liquid Expansion

- Balanced pressurized

- Bi-metallic

- Bellowed

- Venturi Nozzle steam trap

More Resources: Steam Trap: Purpose, functions, types, working, Codes, selection, maintenance.

Thermodynamic Steam Trap

A thermodynamic steam trap operates on the principle of difference in dynamic pressure of steam and condensate. Here, the discharge of condensate happens at the same temperature as steam. In the trap body steam enters, expands suddenly when it reaches the backside of the disc.

This expansion of steam on the backside of the disc results causes high flow velocity and decreases the pressure under the disc. Steam above the disc gets high-pressure force and the action of balance forced on disc helps to close trap disc on its seat.

Thermodynamic steam traps are a kind of phase detector. They can easily differentiate between liquid and gases but not able to differentiate between steam and air or other non-condensable gases. Therefore, they have less ability to discharge these gases and during discharge, some amount of steam also passes.

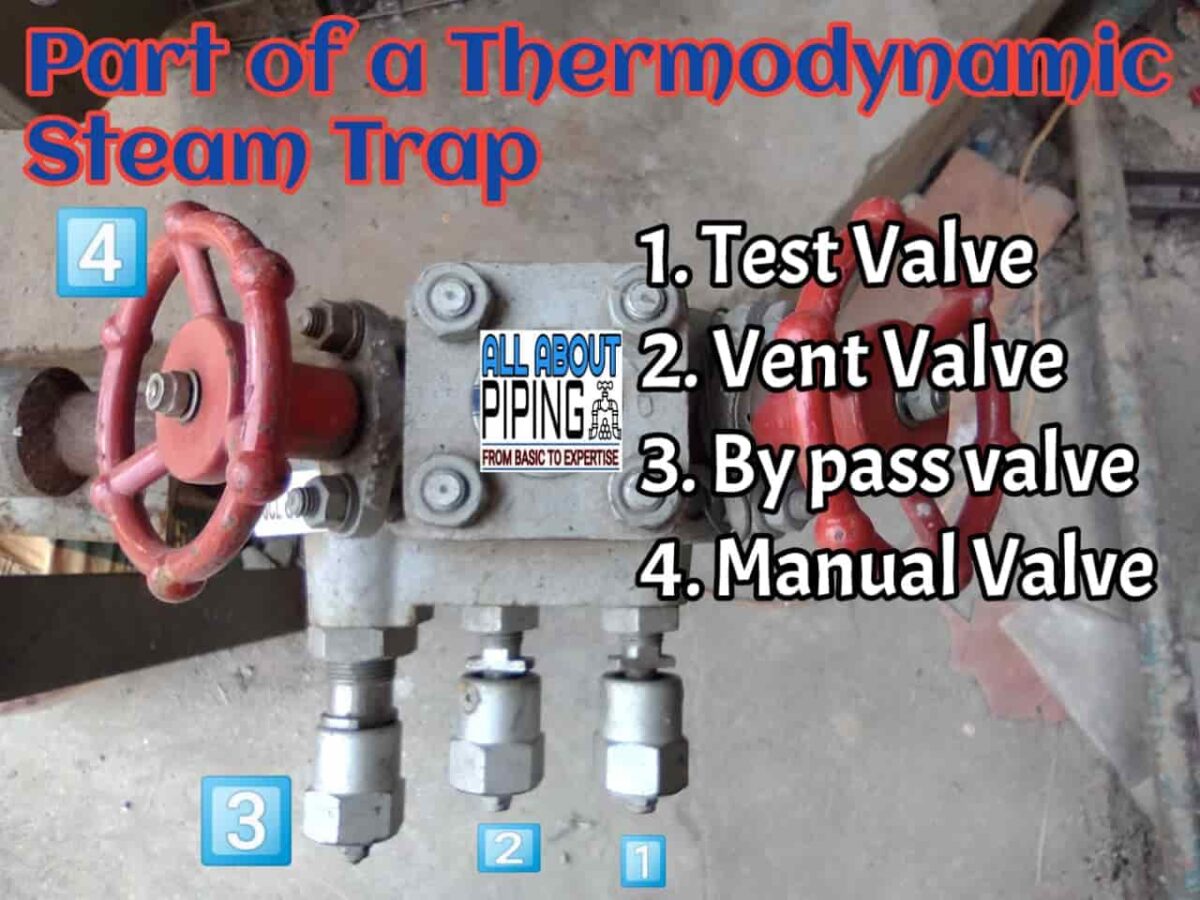

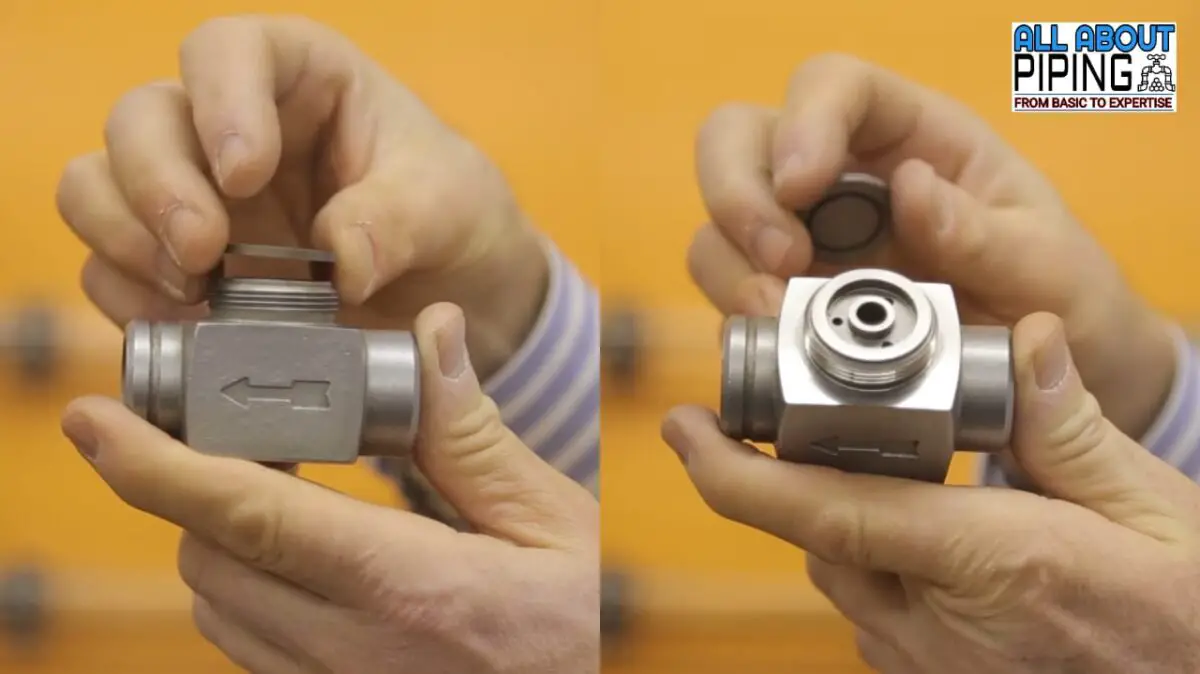

Disc Type Steam trap

Disc-type steam has a metallic disc covering a small hole in the trap body. Because of the presence of a disc in the steam trap, it is called disc type steam trap. When steam moves with high velocity, this creates a low-pressure zone that closes the disc.

After the formation of condensate, this pressure increases, and the disc leaves the trap body surface to allow discharge of condensate from the trap body.

Disc Steam trap Operation

Disc type steam trap working principle is based on Bernoulli’s theorem. According to Bernoulli’s law, the sum of the static pressure and dynamic pressure is constant at all points in fluid flow in a system.

When low-temperature condensate flows in the steam trap on start-up, the valve disc is forced upwards and the condensate is discharged from the outlet hole of the trap body. As the start-up phase grows condensate becomes hotter and pressure rises.

Part of the static pressure is then gets converted to velocity in the steam trap body between the seat and the disc. This causes to disc to shut the discharge flow and trap steam.

Advantages of Disc Steam trap

- No requirement for any adjustment of calibration.

- Compact, simple, and lightweight body design.

- Can be used for high-pressure and high-temperature steam.

- No specific installation orientation requirement.

- Highly durable and withstand with water hammering.

- Performance can be easily checked in the field.

Disadvantage of Disc steam trap

- During the start, its air handling capability is very less that can cause a stuck disc.

- Excessive back pressure in the return system can prevent the disc to close.

- High noise during condensate discharge.

- Dirt can increase the work cycle rate that increases the wear of the disc.

- Sensitive to environmental conditions. Cold weather can lead to improper working of the trap.

Must to Know: Horizontal Centrifugal Pump vs Vertical Centrifugal Pump: Functionality, Selection, Advantages, Uses

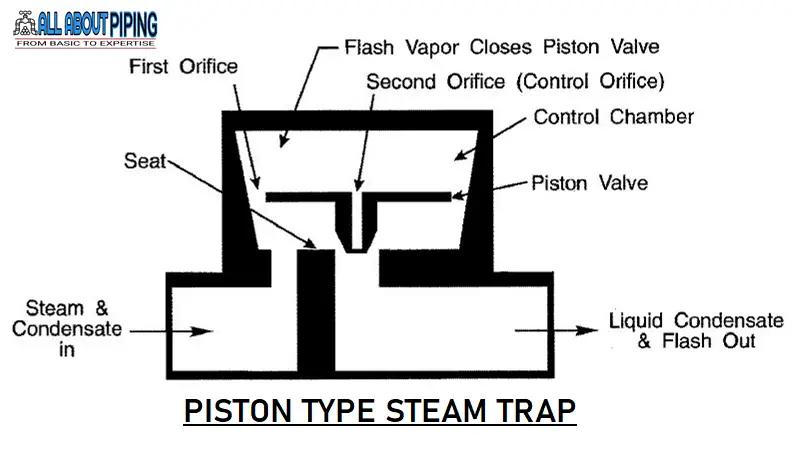

Piston type Steam Trap

A piston steam trap has internal construction like a piston valve that lays on its seat to stop the discharge of steam. Piston steam trap utilizes the heat of condensate and kinetic energy of steam to move the piston from its position.

Like a disc steam trap, a piston steam trap is also a phase detector that senses the difference between liquid and gas. But as the negative aspects of thermodynamic steam trap, this can’t differentiate between steam and other non-condensable gases.

Operation of Piston Type Steam Trap

During the initial charging of the steam system, Pressure created by the condensate lifts the piston valve, allowing discharge of condensate. During this process in the control chamber pressure attains a low value because of the control orifice in the piston.

Because of this control orifice of the second orifice more condensate can be supplied to the control chamber through the first orifice of the trap. When the temperature of the condensate comes closer to steam temperature, condensate in the control chamber converts into flash steam according to the laws of thermodynamics.

This flashing of condensate in the control chamber stops the flow of steam through the control orifice, which causes an increase in pressure nearby the control chamber. Because of this increased pressure, the piston valve sticks to its seat and closes the chamber to prevent steam flow through the trap.

When with respect cooler condensate reaches the trap, it causes the control chamber pressure to drop and flashing stops and the trap opens to discharge condensate and repeats the cycle again.

Advantages of Piston Type Steam Trap

- Suitable for high-pressure steam system

- Good response to the change in condensate load condition.

- Highly durable and withstand even with water hammer.

- Self-draining and don’t get damaged by freezing.

- Function not getting affected in case of superheated steam.

- Good Air handling capability.

- Small Size and lightweight.

Disadvantages of Piston Type Steam Trap

- Excessive backpressure in return system can prevent trap from closing.

- Noisy operation.

- Comparatively higher steam loss.

Featured Post: What are High Point Vent and Low Point Drain? Why it is required?

Mechanical Steam Trap

Mechanical steam traps are built with a float that responds to change in the density of fluid and condensate level. The mechanical steam trap uses the density difference between steam and condensate to detect the presence of condensate.

Float of mechanical steam is hinged with the outlet port of the trap body that allows or stop condensate according to its level in the trap body.

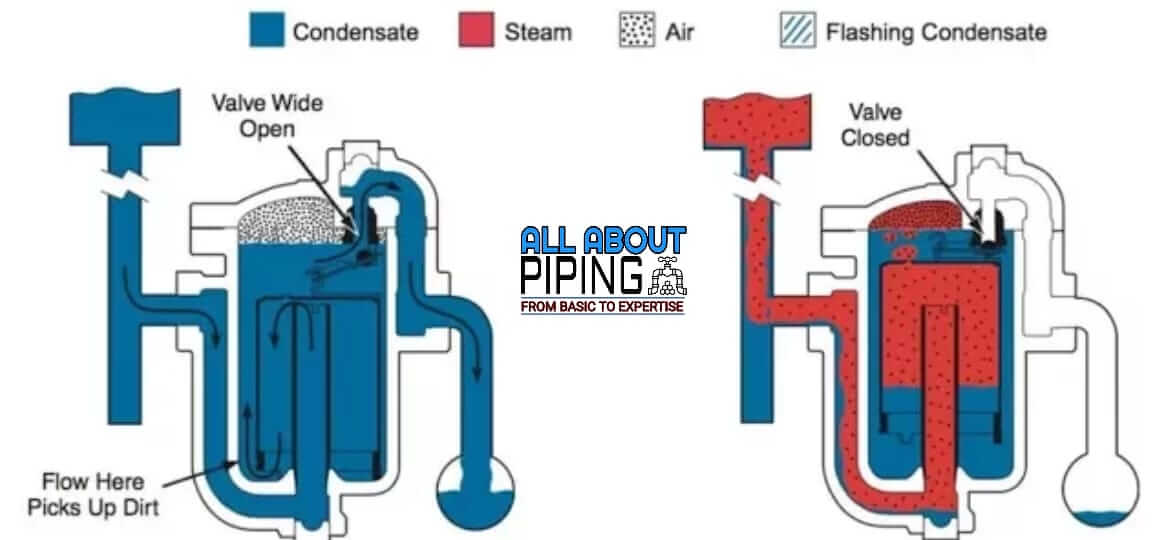

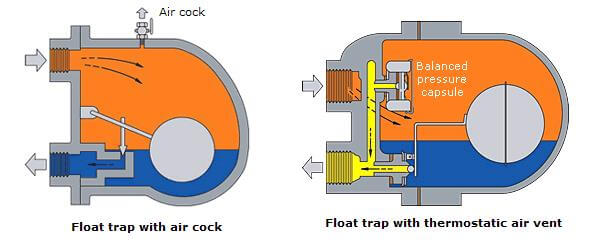

Float Type Steam Trap

A float type steam trap operate on the density difference of fluid in the trap body. In the steam trap shown in above image, trap is always flooded with condensate and neither steam nor non-condensable gas can pass through it.

So, in these trap early design a manual operated valve were provided to manual vent this air during startup. Now a day with latest technology, Modern traps use a thermostatic air vent that allows initial air to pass while trap is holding condensate.

This automatic air vent uses a balanced pressure capsule element and is located just above the condensate level. After releasing the initial air this remains close until another amount of air or non-condensable gas doesn’t accumulate in the steam trap.

Working of float type steam trap

In a float steam trap, a lightweight segment of the steam trap is hinged to the outlet nozzle of a steam trap. This hinge act like a gate for the steam trap. In the trap body when condensate is filled float moves upwards and the hinged gate to the floating lever allows condensate to discharge from the steam trap body.

Here, Density plays a vital role in the working of a steam trap. The density of float installed in a trap is lower than condensate but higher than steam. When condensate accumulated in the steam trap a buoyancy force acts on the float that forces float to glide above the condensate.

Advantage of float type steam Trap

- This can continuously discharge condensate. This makes a great choice for using this in a steam system where rate of heat transfer is high.

- Able handle heavy and light condensate load equally.

- Not affected by sudden fluctuation of pressure.

- This can discharge air and non-condensable gases without disturbing condensate.

- Resistant to water hammer.

Disadvantage of float type steam Trap

- Can be damaged with severe freezing.

- Can be mounted in one position only.

- If a trap is subjected to higher differential pressure than intended, it will close and not pass condensate.

Inverted Bucket Steam Trap

As the name suggests, the Inverted bucket steam trap is equipped with a bucket in an inverted position that obstructs the steam and releases condensate and non-condensable gases. This type of steam trap always time submerged in the condensate, hence it is also called the Inverted submerged bucket steam trap.

The most essential part of the inverted steam trap is “A small air vent hole” in the top of the bucket. this allows accumulating all non-condensable gases like CO2 at top of the trap body and discharges it when the bucket drops down from its lifted position because of the bouncy force of steam.

Inverted Bucket steam trap Working Principle

After installation, Before the startup bucket stays at the bottom of the steam trap, and the lever attached to the bucket keeps the valve in a fully open position. when steam starts to pass through the steam trap this lifts the bucket upward and its lever arrangement closes the valve.

After losing latent heat, steam converted into condensate and the trap body starts to fill with condensate all around the bucket. when condensate up to some level, bouncy force applied by steam on bucket starts to reduce and bucket falls gradually.

After dropping the bucket at the bottom of the steam trap lever attached to the bucket allows opening the valve gate. Through this gate first, non-condensable gases get discharged from the trap body and then condensate drained out to some reusable system.

Advantage of Inverted Bucket steam trap

- Simple construction and highly durable with very less or negligible wearing.

- This type of steam trap can withstand with high pressure of the steam system.

- can be used in superheated steam lines with NRV installed at the inlet of the trap.

- Resistance to water hammer.

- Corrosion resistance.

- Resistance against the dirt of steam because of inbuilt strainer in the bucket.

Disadvantage of Inverted Bucket steam trap

- Can’t sustain in low-temperature area, can freeze in a cold environment.

- Priming required before startup.

- Possibility of steam leakage with low load.

- The higher temperature of superheated steam can be a cause of losing traps water seal.

Thermostatic Steam Trap

A thermostatic steam trap is driven by temperature change in the condensate. They operate on the principle that operates on the principle that “Saturated process steam is hotter than either its condensate or steam mixed with condensable gases“.

The thermostatic trap opens its valve for discharging condensate lower when it detects lower temperatures. this steam trap operates in response to the surrounding temperature. The operation and benefits of each of its types i.e. Liquid expansion, Bimetallic, and balanced pressure thermostatic steam trap explained in the next sections.

Liquid Expansion Steam Trap

This is one of the simplest types of thermostatic traps. In this type of trap, an oil-filled section expands and contracts according to heat gained by steam and condensate. This movement of the element of the steam trap allows it to discharge non-condensable gases and condensate that makes it ideally suited for discharging a large amount of condensate.

The normal working range of the Liquid expansion steam trap is between 60 degrees Celsius to 100 degrees Celsius. Because of its response towards temperature change, this trap is can be used “Condensate drain trap“

In Liquid expansion traps, the outlet is always pointed upwards to enable continuous immersion of oil-filled elements. It can be installed alongside a mains drain trap which is normally connected to a condensate return line.

Liquid expansion steam trap operation

This is the nature of oil that, when it gets the heat it expands and its volume increases accordingly its volume decreases when oil losses heat. this basic fundamental nature of oil helps this trap to perform for trap steam and discharging condensate from it.

In a liquid expansion steam trap, there is a piston-like arrangement in an oil-filled chamber. the tip of this piston is so arranged that when this moves sidewise this will open and close the valve gate accordingly.

When steam gets in contact with this oil, this expands and its volume increases. this expansion of oil helps the piston to move sidewise and allows it to rest on the valve seat to take a closed position. After losing latent heat and converted into a condensate trap’s piston takes its previous position to open the trap and allows it to drain condensate and non-condensable gases.

Advantage of Liquid Expansion Steam Trap

- Can be adjusted to drain even in low temperature.

- This can withstand vibration and water hammer conditions.

- This fully opens when flooded with cooler condensate that helps to quickly and completely drain condensate on startup load.

- Can discharge a high volume of condensate at once.

Disadvantages Liquid Expansion Steam Trap

- The flexible tubing arrangement can corrode and destroy because of condensate and high temperature.

- Not effective during low-temperature weather conditions.

- This can’t be used for a steam system that requires immediate removal of the trap.

Balance Pressure Steam Trap

With technology, the functionality of the steam trap also evolved to gain a better way to handle steam and to use it for its optimum efficiency. As a result of improvement on liquid expansion steam trap, balanced pressure steam trap is invented for industrial application.

The operation of a balanced pressure trap is affected by surrounding steam pressure. In this type of trap, a sealed pod (Capsule) containing a special liquid-water mixture is installed. The boiling point of that mixture is below that of water.

In cold conditions or during start-up, the capsule is in a relaxed position, which means in this capsule there is not any pressure developed because of the liquid-water mixture. In this condition, the valve is not on its seat and the trap is wide open. This feature of a balanced pressure steam trap is well suited for air venting during start-up without any steam loss.

Working of Balance Pressure Steam Trap

When condensate passes through the balanced pressure steam trap, heat is absorbed by the liquid-water mixture of the capsule. That mixture starts to vaporize before steam reaches to steam trap. The vapor pressure of the capsule forces this to expand and close the valve.

Heat loss from the trap then cools the water beside the capsule. The vapor formed in the capsule condenses and capsules contract resulting in the opening of the valve and discharging of condensate and air until steam reaches again in the trap and the cycle repeats itself.

Advantages of Balance Pressure Steam Trap

- Small in size and tight closure of the valve.

- Valve stays in fully open condition during start-up allowing air to release.

- Very few chances of freezing.

- Self-adjustment according to steam pressure for its maximum allowable pressure.

- Easy maintenance and repair.

- Able to withstand vibration and water hammering.

Disadvantage of Balance Pressure Steam Trap

- This type of trap doesn’t open until condensate pressure drops to a temperature lower than the boiling temperature of the liquid-water mixture.

- An older balanced pressure steam trap has a bellow that can be damaged by a water hammer and corrosive condensate.

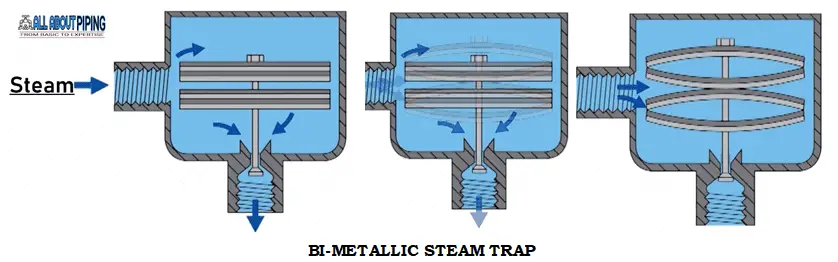

Bi-metallic steam trap

When metal is heated up to a certain temperature this expands and every metal expands differently at different temperatures. This nature of metal is used in the bimetallic steam trap for its working.

As per the name, A bimetallic steam trap is formed using two different metal strips and welded together to form a single strip. When both get heated, because of the different nature of metals earlier expansion in one metal strip will cause a bending moment in the complete welded strip.

Here, 02 important point need to consider regarding this simple mechanism of bimetallic strips:

- The steam trap starts to work after a certain fixed temperature. This condition may not satisfy the pressure and temperature requirement of a steam trap.

- Because of the force developed by the bending moment of a single bimetallic strip, a large portion of other metals reacts to the temperature change.

Bi-Metallic Steam Trap Operation

In bi-metallic steam trap, conical end steam acts as a gate to open and close the valve according to metal strip action. As the composite strip is consists of two metallic plate of different expansion coefficient are the main components of this trap.

When steam comes to the trap body chamber, the bimetallic strip gets compressed and the lever attached to it helps the conical gate to close the discharge door. After steam gets converted into condensate temperature falls, and the compressed bimetallic strip attains its original position to open the gate to release air and condensate from the system.

Advantage of Bi-Metallic Steam Trap

- Compact in size but can handle a high amount of condensate from the steam system.

- Have good air venting capabilities and complete draining of condensate.

- steam traps can’t be damaged even in a freezing environment.

- Because of metallic strips, this can handle water hammering, corrosion, and high steam pressure.

- This can be installed in any orientation required.

- can work efficiently in higher temperature and higher pressure conditions.

- Rugged, self-draining, and energy-efficient.

Disadvantage of Bi-Metallic Steam Trap

- Discharge of condensate below steam temperature can cause waterlogging in the trap body.

- Its reaction time is not so quick which causes steam loss.

- Dirt particles can prevent the tight closing of the valve.

- Discharging against the backpressure requires cooling down condensate at 50% lower temperature.

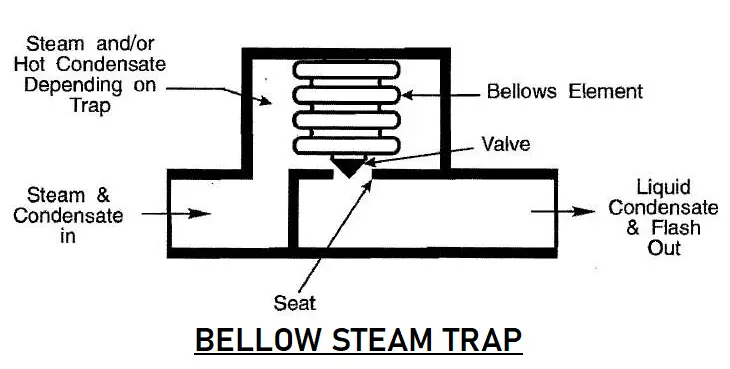

Bellowed steam trap

Bellow steam traps are thermostatic traps that respond according to the change in temperature and pressure of the steam to open and close the valve. In this type of trap, the actuator of the valve is a bellow filled with vaporizing liquid.

One end of the bellow is fixed while another one is free for a movement that opens or closes the valve according to the response of pressure change by the liquid inside the bellow. The most frequently use actuating material for bellow steam traps is corrugated bellows. Single diaphragm capsules are also used here.

Operation of Bellowed Steam Trap

The operational principle of bellow type steam trap is somehow similar to the balanced pressure steam trap. Here also stem of the valve is controlled by pressure generation because of liquid-filled inside the element of the trap.

Initially, bellowed steam trap is in the open position during start-up. When steam reaches up to the trap because of heat gain by inside liquid of the bellow, it starts to vaporize and expands the bellow. Because of which its cone-shaped gate rests on it seat and closes the valve tightly to trap steam inside.

As condensate starts to form temperature drops and the internal pressure of bellow decreases and the valve attains an open position to allow discharge of air and condensate from the trap.

Advantages of Bellowed Steam Trap

- Excellent air handling capability.

- Energy-efficient

- self-draining

- various discharge temperatures.

- can be mounted in several positions.

- Simple construction and easy to maintain and replace internal parts.

- Small size and weight.

Disadvantage of Bellowed Steam Trap

- Bellows elements tend to be failure-prone, especially when subjected to water hammers.

- Difficult to check while operating in throttling mode.

- Generally not suited for higher pressure.

- Limited superheat capability.

- Short stroke diaphragm design susceptible to dirt-initiated failures.

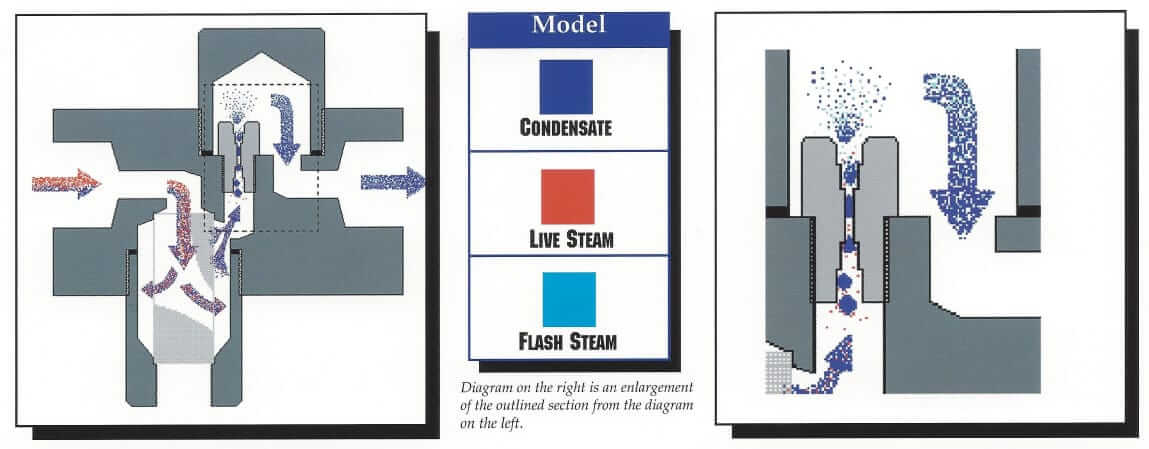

Venturi Nozzle steam trap

In steam trap types, Venturi Nozzle serves as an efficient condensate removal device by taking advantage of physical differences of specific volume between steam and condensate. In this type of steam trap, a venturi-shaped nozzle is installed at the outlet nozzle of the steam trap. that helps steam trap to distinguish between condensate and steam.

Working of Venturi Nozzle steam trap

The condensate is denser and travels at a much slower speed than live steam. Because of condensate slower speed, it prevents the passage of steam from the venturi. When condensate exists from the diverging section of the venturi nozzle, some part of it starts to flashing which increases a specific volume and creating a choking effect that creates a hindrance for steam to discharge from the steam trap.

Advantage of Venturi Nozzle steam trap

- No moving parts in the steam trap.

- Suitable for high-pressure steam system application.

- Highly durable and can withstand water hammering.

- No damage by freezing.

- Superheated steam can also be managed well without loss of its efficiency.

- Can be installed in any position.

Disadvantage of Venturi Nozzle steam trap

- Venturi Size must be selected carefully, each steam trap needs special attention as per its location and size.

- this can’t respond to varying condensate loads.

- Oversized venturi can make the steam trap inefficient.

- Dirt particles of steam affect its performance.

- If no condensate is present in the trap body, this allows steam to pass from the outlet.

More to Read: Vacuum Ejector System: Purpose, Selection, Working, Advantages