When a piping network is being designed, A tapping connection with valve for isolation and end blind connection of approximately a total length not more than 300mm is also provided. The open-end of a tapping connection is on the Topside, It is called a vent, while a tapping connection with the downside open end is called a drain.

There can be multiple drains and vents in a single piping system. But a high point vent and Low point drain will be only in one quantity each. The other types of Drain or vent will include Process Drains and vents too.

These Process Drain and vents are useful for charging a piping system for the first time and for its maintenance. While High point vent and Low point drain are actually hydro test drain and Vent that has a purpose during hydro testing of the piping system only.

In this article ” High point vent and Low point drain ” we will provide you a detailed description about these drains and vent that will help you to understand the following along with purpose and functionality these:

- What are High point vent (HPV) and Low point drain (LPD)?

- How do these drain and vents work?

- Purpose of HPV and LPD?

- Design detail and position selection. and

- Overview about Wet vent

More to Read: What is a Coriolis flow meter and how this works?

Table of Contents

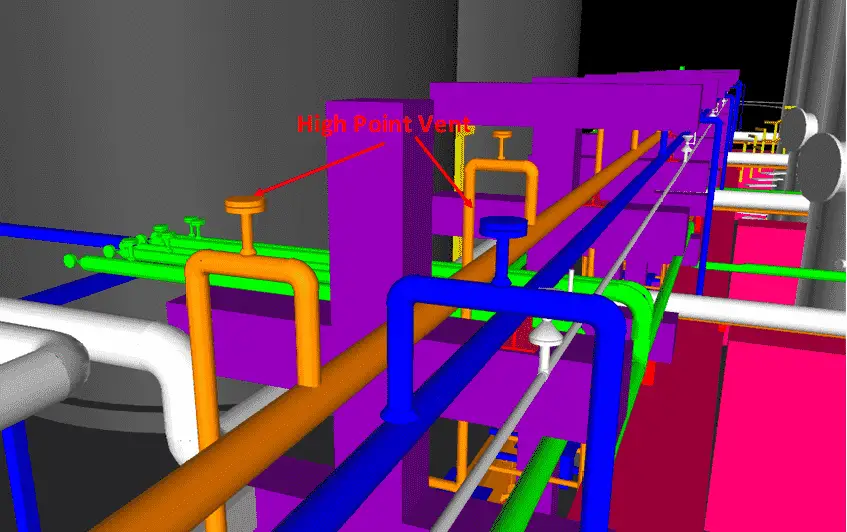

High point vent

In a Piping system, there can be more than one tapping connection that can be called a vent. But a vent tapping installed at the highest elevated point of the Piping network is called a High point vent. This vent tapping connection is sometimes installed with a gate valve for air venting during the hydro test.

A high-point vent in piping is finally closed by installing a cap or plug for permanent closure. If that vent is designed to work as a process vent and hydro test vent both then this has a flanged end connection. So that, it can be opened whenever required.

Purpose of High point vent or HPV

Each plant with a piping system must be insured properly for quality of fabrication, Installation, and Sustaining in designed pressure. To test its sustainability complete piping system is pressure tested normally by filling water in the pipe.

During the filling of water, it is mandatory to evacuate all air particles from the piping system for not letting pressure down while compressing the water. To fulfill this requirement we need to provide a venting point at the highest location of the piping network.

The high point vent helps to evacuate all air particles from the piping system so that no air bubble can form and no pressure drop will be there because of uneven molecule distribution for compression.

How high point vent (HPV) works?

During filling of water in the pipe, when it is required to evacuate air from the Piping network HPV needs to keep in open condition. After complete fill-up of water in pipe some amount of water needs to overflow from High point vent for the hydrotest to get assured of venting of all air particles.

Generally, Water venting or overflow from HPV is done for 15 minutes or depends on the complexity of the piping network and total pocket depth of the piping loop. And then closing the high point vent valve for pressurizing the line.

Since a high point vent is there to release all air in the pipe during the hydro test, Sometimes it is also referred to as a high point air vent because of its functional nature.

Featured Article: What Is RF Pad? How To Calculate Reinforcement pad dimensions?

Low Point Drain

Quite the opposite for LPD, Drain tapping installed at the lowest point of a piping system is called Low point drain. Low point drain also consists of a valve which generally called “Low point drain valve”. This is being used to empty the piping system after hydrotest.

A low point drain can also be used as a process drain, but in that case, it is not closed with low point drain caps or low point drain plug but Like a High point vent it has also a flanged connection that is blinded after a pressure test.

Valves of Low point drain should be highly durable to avoid and any dripping because of low point drain leaking and also low point drain valve replacement because of any damage.

Purpose of Low point drain (LDP)

After Pressure testing of the piping system which is often done with water, it is important to drain all water from the pipe so that no rust can develop on the internal surface of the pipe and reduce its wall thickness.

A low point drain near equipment can also be treated as a process drain during maintenance for draining the tank, vessel, filter, etc. For this LPD must be installed with valve and flange arrangement.

How low point drain (LPD) Works?

During draining of water after hydrotest this becomes a matter of fact that, “How to open low point drain?” because the direct opening of only LPD will create a vacuum in a piping system that may damage and destruct pipes.

To avoid this disruption, it is mandatory to open a High point vent before opening the Low point drain. Doing so will release pressure inside the pipe and provide a way to enter the air in the pipe to maintain the same atmospheric pressure inside the pipe during draining.

Design details for High point vent and Low point drain

A high point vent and low point drain is generally a branch connection taken from coupling or Sockolet. The size of HPV or LPD is normally 0.75″ which consists of the following items:

- Nipple, 0.75″x100mm = 02 Nos.

- Valve , 0.75″ = 01 Nos.

- SW flange 0.75″ = 01 Nos.

- Blind Flange, 0.75″ = 01 Nos.

- Coupling or Sockolet, 0.75″ = 01 Nos.

The pressure rating of each pipe fittings depends on the design pressure of the Piping system.

More Resources: ASME B31.3 2014 edition

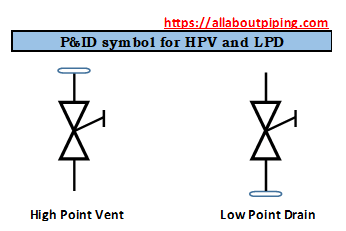

P&ID symbol for High point vent and Low point drain

P&ID symbol for high point vent or low point drain is same as any other drain and vent of the piping system is as follows:

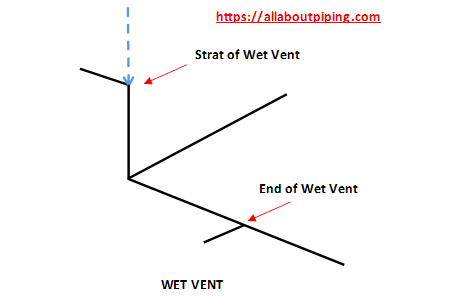

What is a wet vent?

The wet vent is actually a plumbing term. this is a junction in the plumbing system where a “Tee-section” is installed. This Act as Vent as well as the drain. In an ideal case, the drain and vent should be separate so that proper venting will be there to avoid any blockage. But sometimes operation of drain and vent is not just practical.

Consider, you want to install a bathtub to an existing bathroom. In that case, there is no easy way to create a new route with a new vent through the wall and A wet vent is a solution here.

Say, for instance, you want to add a bathtub to an existing bathroom, but there is no easy way to route a new vent up through the wall. A wet vent may be a workable solution.

Conclusion

High Point vent and Low point drain are essential parts of any piping system that helps during hydrotest for proper venting of air and draining of water. Some of the highlighted points are as follows:

- HPV is always installed at the highest point of a piping network.

- LPD is always installed on the lowest point of the piping network.

- A high point vent or low point drain can also act as a process vent and drain.

- After hydrotest HPV must open first to release excess pressure in the pipes.

- The drain valve should be of high durability so that this doesn’t leak or required change in short intervals.