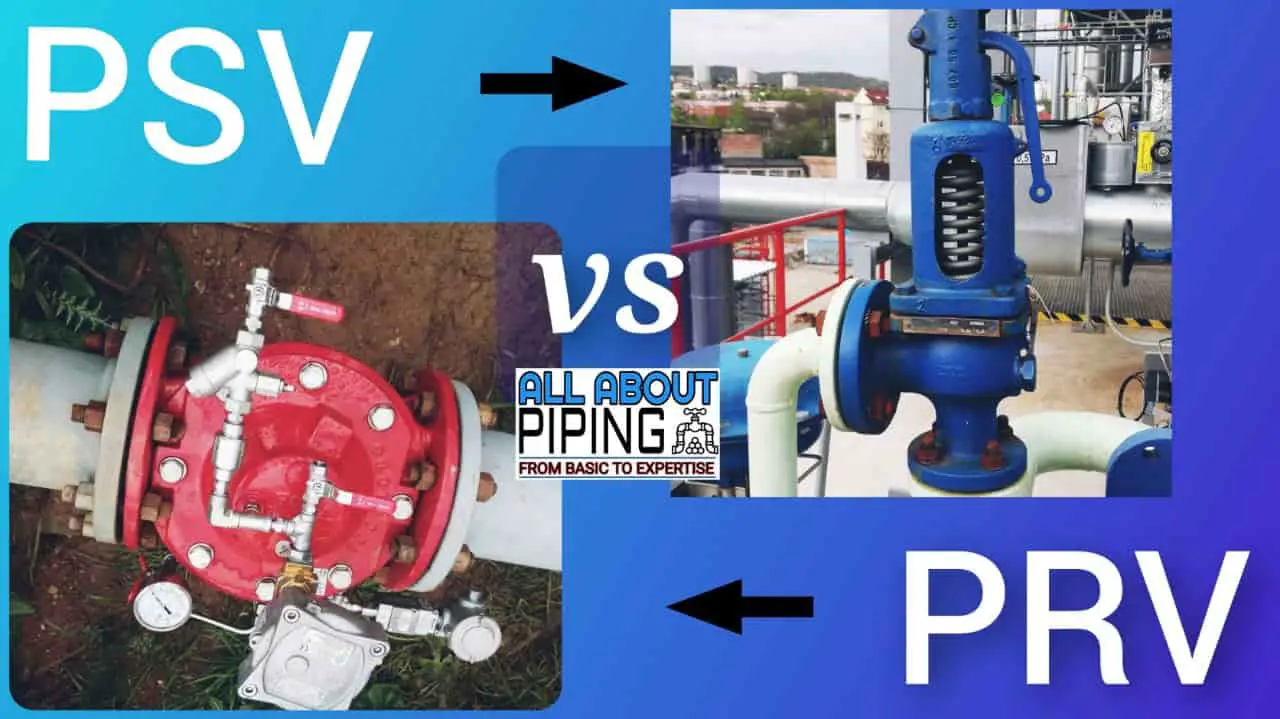

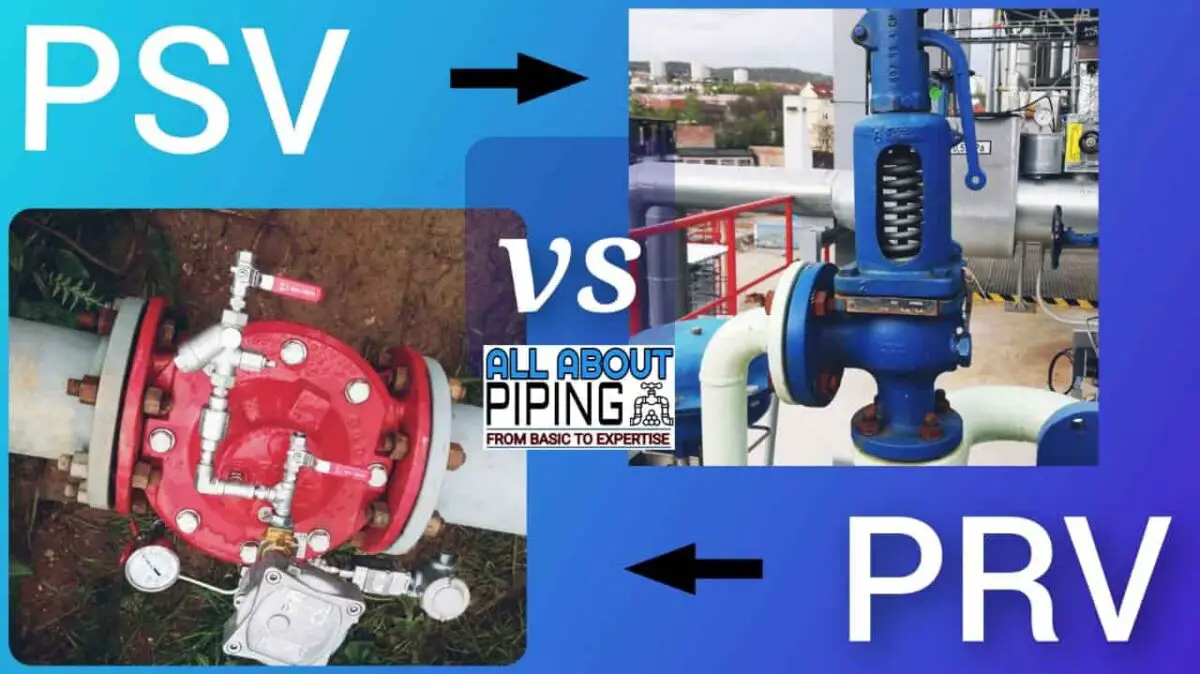

Pressure Safety valves (PSV) and Pressure Relief valves (PRV) are widely used safety devices in any oil and gas or chemical industry. We often install, use, and do maintenance of these pressure safety devices installed for multiple purposes.

It is usually misunderstood about the basic difference of use and functionality between pressure safety valve and pressure relief valve. Knowing those basic differences will help us to identify the need for these piping components and can justify the purpose of their installation.

In this article of “Difference between PSV and PRV,” we will discuss the functionality difference and will understand how PSV is much different from PRV and Different uses of PSV and PRV.

What are PSV and PRV?

PSV and PRV are automated safety devices that serve the purpose of the protection of life, property, and environment during the generation of overpressure in the equipment and piping system.

PSV and PRV are commonly used terms to identify pressure relief devices in a system that generates or operates with pressure. Frequently these terms are used interchangeably and most of the engineers consider them as the same components.

PSV is a valve that is used to secure the pressure on compressible fluid or gas in a pipe or vessel. Opening of PSV is sudden when the pressure in pipe or equipment exceeds the set pressure of the pressure safety valve.

The function of PRV is also to release excess pressure of the system but it is used for an incompressible fluid. The opening of PRV is not sudden. PRV is a valve used to secure the pressure on the vessel, commonly, incompressible fluid, and it should be open in proportional with the pressure condition and therefore the opening of the valve is not sudden.

Difference between PSV and PRV (PSV vs PRV)

PSV and PRV having many differences between each other in terms of functionality, working, uses, and Purposes. Differences with respect to each parameter will be described step by step in the following sections:

- Operation: In normal operations, PRV remains closed and no fluid passes through it. When Pressure rises and exceeds the limit valve opens to protect the system. If PRV fails to reduce excess pressure then PSV pop-up for releasing pressure.

- Functionality: When pressure exceeds the set limit pressure, PSV opens suddenly and releases pressure. While PRV passes fluid gradually as per the increase of pressure in the system. PRV does not open suddenly.

- Fluid Type: PSV is used to install in the piping system where fluid is compressible, eg: Gases. While PRV is designed to relieve the pressure of the incompressible fluid flow.

- Uses: A pressure safety valve is used in Separator, Heater, Scrubber, and filter vessels while a Pressure relief valve is installed to release the pressure of Storage tanks.

- Set Pressure: PSV is designed to actuate automatically to release excess pressure while PRV is designed to limit the pressure in a system within a specific set limit.

- Set Point: The setpoint of PRV is usually set at 10% above the working pressure limit while in the case of PSV, it is set 3% above the working pressure.

- Types: PRVs are divided into pop-type, direct-operated, pilot-operated, and internal relief valve while Pressure safety valve is divided into a wide range according to application and performance.

More to Read:

- Types of Steam Trap: Working, Advantage, Disadvantage

- What are High Point Vent and Low Point Drain? Why it is required?

- Vacuum Ejector System: Purpose, Selection, Working, Advantages

- What Is RF Pad? How To Calculate Reinforcement pad dimensions?