In any industry, building, or storage facility fire protection system must be installed. And firewater Sprinkler is an important protection network. This is a kind of automated system which gets activated because of the detection of rising temperature.

Fire sprinkler systems save many lives. When a fire breaks out, sprinklers control the blaze by discharging water over the fire and preventing flashovers. In this article following details can be learned:

- What is firewater pipig and sprinkler system?

- Components and types of firewater sprinkler system.

- Design and standards of firewater sprinkler system.

- Working and maintenance of sprinkler system.

Featured Article: Welding Hazards and control measures with pdf

Table of Contents

What is Firewater Piping?

In every industry and even in households there is a statutory requirement for the safety purposes of people and properties. Firewater piping is a normal piping system used to suppress the fire with suppressing agents like water, gas, or a mixture of both.

A Firewater piping system is normally made up of carbon steel or galvanized iron. This generally has a red color for easy identification. A standard pressure of 2-3 bar is maintained in no fire condition.

What is the Firewater Sprinkler system?

A firewater sprinkler system is a kind of automated fire suppressing system which can be defined as: ” A suppression or control device that operates automatically when its heat-sensitive element is heated above or equal to its thermal rating.”

When heated this allows water to discharge automatically over a specified area. There is some common misunderstanding that, an automated sprinkler system is activated by smoke but in actuality, they react to heat.

The general requirement for a firewater sprinkler system is the same anywhere regardless of the type of building or equipment unless there is some direct exception in the code. According to NFPA (national fire protection association), full coverage is a must for the entire property unless the standard indicates some deviation.

More Resources: Fugitive emissions testing, Standard and valve stem packing

Components of firewater sprinkler system

The various components of a fire sprinkler system are as follows:

- Alarm Check Valve: Every sprinkler system is quipped with alarm aparatus. When water flows in the alarm valve, electric bell is activated which will alert the people nearby and emergency servises.

- Butterfly Valve: This is installed to regulate flow in the system.

- Check Valve: This allows only one directional flow of water and prevent back flow. In sprinkler system this is used to prevent water in sprinkler system from returning to public water supply.

- Fire Pump: A pump that is used to provide additional pressure to the water supply in order to meet the hydraulic design requirement of the system.

- Fire Sprinkler head: It is device that in the event of fire open-up and discharge water automatically.

- Pressure Gauge: This is installed to measure water or air pressure in the sprinkler and standpipe system. According to NFPA25, gauge must be replaced every 05 year.

- Hangers: This is the component that hold the sprinkler pipe. Hanger also need to be attached to some rigid structure.

- Jockey Pump: A small pump is used in conjuction with main fire pump, that is connected to fire sprinkler system. Jockey pump is used to make small pressure fluctuation the system.

Types of Firewater Sprinkler

There are 04 types of firewater sprinkler systems. Each of these systems helps to prevent fire from spreading and reduces any damage from fire. The main difference among these sprinkler systems is how they get activated. The types are as follows:

- Wet pipe fire sprinkler system

- Dry pipe fire sprinkler system

- Pre-action fire sprinkler system

- Deluge fire sprinkler system

Wet pipe fire sprinkler system

This is the most common type of sprinkler system. it contains water in its pipe system even before its being activated. Since water is the present facility where it is installed must maintain a temperature of at least 40°C. This temperature is required to prevent the water from freezing in the pipes.

Activation: The process to activate a wet fire water sprinkler system is simple. When the fire sprinkler reaches a designated temperature, the bulb breaks out and water gets released.

This system is generally installed in office buildings, schools, high-rise equipment, and buildings with some ordinary hazards. This system is also called the standard response sprinkler system. This is the slowest sprinkler system. 5mm Sprinkler thermal bulb gets activated slowly only when some set temperature reaches.

Dry pipe fire sprinkler system

Unlike wet pipe systems, dry-pipe fire sprinklers are not filled with water. Instead, it is filled with nitrogen or pressurized air. The air pressure holds a dry pipe valve closed and prevents water from entering the system.

Activation: When the fire sprinkler detects a rise in temperature it gets activated and air pressure drops in the sprinkler system. This causes the dry sprinkler pipe valve to open and floods water into the dry pipe. Then activated fire sprinkler discharges the water.

Since dry pipe fire sprinkler contains no water, they are ideal in the areas where the temperature is low and water gets freezes. Unheated warehouses, parking garages, and attic spaces are usually equipped with this type of fire protection sprinkler system.

Because of its 3mm thermal bulb, its response is faster at a designated temperature. these sprinklers release water higher water rate over the fire zone to prevent any hazard.

Pre-action fire sprinkler system

Like, dry sprinkler system, this is also filled with pressurized air or nitrogen instead of water. Activation of this system is a 02 step process.

Activation: First, a heat or smoke detector detects fire which sends a signal to open the pre-action valve. This fills the complete piping system with water.

Next, when a fire sprinkler head detects an increase in temperature sprinklers discharge water immediately on fire.

A two-step process of activation helps prevent accidental system activations. This makes this type of fire sprinkler system idea for installation in museums, server rooms, and libraries.

Deluge fire sprinkler system

A deluge fire sprinkler system is installed in high hazard facilities because the open-style sprinkler head can discharge water quickly. unlike the other type of sprinkler system, heads of this sprinkler system remain open and activated always at once.

Activation: This system neither contains water nor pressurized air. Once heat or smoke gets detected deluge valve opens and sends water to all the fire sprinklers. This allows discharging of water from each sprinkler head.

When highly combustible material catches fire, flames can grow and spread immediately. This is the reason this sprinkler system is installed in facilities like aircraft hangers, Refineries, chemical plants, and manufacturing companies for fact acting deluge fire sprinkler systems.

Unlike standard response or a fast response sprinkler, open fire has no thermal elements and its nozzles are completely open and ready to discharge with detection of fire.

Firewater sprinkler system design

During firewater sprinkler system design following points needs to be followed:

- Fire water main network pipe size should be calculated and based on design rate at a pressure 10 bar.

- The maximum allowable flow in the system should be 3.5m/s.

- It is assumed that 30% of firewater evaporates while extinguishing fire. This figure shall be taken into account for design draining system.

- Under non-fire condition, the system shall be kept full of water and at a pressure of 02 to 03 bar gauge by means of jockey pump. if jockey pump is used, it shall be spared and both pumps shall have of capacity of 15m3/h to compensate for leakage.

- The firewater ring main system should be equipped with hydrants.

- A single water line connected to ring and main system shall run along the jetty approach to the jetty deck. the line shall be fitted with a block valve located at a distance of about 50m from jetty deck.

- Turbulence also creates pressure loss. So, valves and fittings should be installed in minimum quantity to minimize it.

NFPA standard for fire protection

Following standards are to be followed case to case for fire protection and fire hazard elimination:

| NFPA 3 | Standard for Commissioning of Fire Protection and Life Safety Systems |

| NFPA 4 | Standard for Integrated Fire Protection and Life Safety System Testing |

| NFPA 10 | Standard for Portable Fire Extinguishers |

| NFPA 11 | Standard for Low-, Medium-, and High-Expansion Foam |

| NFPA 11C | Standard for Mobile Foam Apparatus |

| NFPA 12 | Standard on Carbon Dioxide Extinguishing Systems |

| NFPA 12A | Standard on Halon 1301 Fire Extinguishing Systems |

| NFPA 13 | Standard for the Installation of Sprinkler Systems |

| NFPA 13D | Standard for the Installation of Sprinkler Systems in One- and Two-Family Dwellings and Manufactured Homes |

| NFPA 13R | Standard for the Installation of Sprinkler Systems in Low-Rise Residential Occupancies |

| NFPA 14 | Standard for the Installation of Standpipe and Hose Systems |

| NFPA 15 | Standard for Water Spray Fixed Systems for Fire Protection |

| NFPA 16 | Standard for the Installation of Foam-Water Sprinkler and Foam-Water Spray Systems |

| NFPA 17 | Standard for Dry Chemical Extinguishing Systems |

| NFPA 17A | Standard for Wet Chemical Extinguishing Systems |

| NFPA 18 | Standard on Wetting Agents |

| NFPA 18A | Standard on Water Additives for Fire Control and Vapor Mitigation |

| NFPA 20 | Standard for the Installation of Stationary Pumps for Fire Protection |

| NFPA 22 | Standard for Water Tanks for Private Fire Protection |

| NFPA 24 | Standard for the Installation of Private Fire Service Mains and Their Appurtenances |

| NFPA 25 | Standard for the Inspection, Testing, and Maintenance of Water-Based Fire Protection Systems |

| NFPA 72® | National Fire Alarm and Signaling Code® |

| NFPA 75 | Standard for the Fire Protection of Information Technology Equipment |

| NFPA 76 | Standard for the Fire Protection of Telecommunications Facilities |

| NFPA 92 | Standard for Smoke Control Systems |

| NFPA 96 | Standard for Ventilation Control and Fire Protection of Commercial Cooking Operations |

| NFPA 115 | Standard for Laser Fire Protection |

| NFPA 170 | Standard for Fire Safety and Emergency Symbols |

| NFPA 200 | Standard for Hanging and Bracing of Fire Suppression Systems |

| NFPA 204 | Standard for Smoke and Heat Venting |

| NFPA 291 | Recommended Practice for Water Flow Testing and Marking of Hydrants |

| NFPA 408 | Standard for Aircraft Hand Portable Fire Extinguishers |

| NFPA 715 | Standard for the Installation of Fuel Gases Detection and Warning Equipment |

| NFPA 720 | Standard for the Installation of Carbon Monoxide(CO) Detection and Warning Equipment |

| NFPA 750 | Standard on Water Mist Fire Protection Systems |

| NFPA 770 | Standard on Hybrid (Water and Inert Gas) Fire Extinguishing Systems |

| NFPA 1150 | Standard on Foam Chemicals for Fires in Class A Fuels |

| NFPA 2001 | Standard on Clean Agent Fire Extinguishing Systems |

| NFPA 2010 | Standard for Fixed Aerosol fire-extinguishing Systems |

K-factor for firewater sprinkler system

K-factor for the firewater sprinkler system is defined as the water discharge coefficient permitted through the sprinkler. In simple terms, the K-factor of the sprinkler system provides the details of the rate of water to be discharged from the sprinkler.

The K-factor depends on the orifice diameter of a sprinkler. A low K-factor for eg. K2.8 restricts the flow of water. While a larger K-factor for eg. K22.4 permits more amount of water discharge. K-factor is originally created to be in multiple of K5.6 sprinkler as reference. For Example, A K2.8 sprinkler provides 50% less discharge rate of water while K11.2 will discharge 200%.

The discharge from a sprinkler head or water from a sprinkler nozzle can be calculated from the formula below:

q = kp0.5

where:

q = flow

k = nozzle discharge coefficient or k-factor for head/s[rinkler

p = pressure

So, the pressure developed by discharge water rate can be calculated as:

p = ( q / k )2

Firewater sprinkler system installation

In any facility residential or commercial, a fire sprinkler system needed to be installed by only a certified company. The hardware such as pipe, fittings, QBD can be installed from any third party with TPI certification. Few installation guidelines that need to be followed are:

- Design of sprinkler should allow it to discharge water on all area in its vicinity of installation.

- Sprinkler system pipe shall not pass directly over electric panel boards, switchboards, motors or any electrical equipment.

- All discharge water shall discharge either outside of building in the water trench or sump pit.

- All risers and test points shall not be higher that 6 ft. above paving floor with a common drain line.

- A 2″ Nominal Bore full port ball valve need to install at the discharge end of the drain line allowing the drain to be charged to prevent water motion when tampering occurs.

- A sight glass should be installed just after the valve but before drain line.

- An accessible pressure gauge near the topmost outlet of each standpipe.

- A red and white label on ceiling grid to indicate test stations or any valves.

Working of Firewater sprinkler system

A sprinkler system is very much an important part of the fire protection system. This can prevent properties from getting damaged and reduce the risk of injury to people working nearby.

Understanding the working philosophy of the Firewater sprinkler system is staged into 03 steps which are:

- Detection

- Activation and

- Termination

Detection of fire

Fire sprinkler systems are strategically installed sprinkler heads with glass bulbs containing a glycerin-based liquid. This bulb of sprinkler head detects fire through the rising temperature from a nearby location.

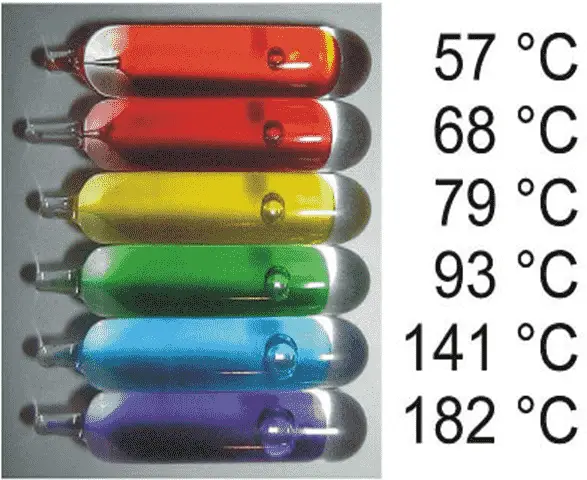

As the temperature reaches the set temperature according to the installed bulb. The liquid inside the bulb expands and breaks the glass and the sprinkler head is activated. There are multiple colors of bulbs available according to their temperature range. Different colors are mainly to define at which temperature the sprinkler system will get activated.

Activation of sprinkler system

Depending on the bulb used in the sprinkler system, activation can vary. Once the glass bulb breaks, the sprinkler head releases water. However, the pressure of water stored and is delivered through pipes depends on the fire sprinkler system.

Water stored in the wet pipe system is released immediately when after the detection of heat by the bulb. And dry pipe system that stores water behind the valve needs to be released before the water can flow through the pipe.

Termination of fire

After the activation of the sprinkler, system water is released on the fire to terminate the cause of the fire. Wet pipe, dry pipe, and pre-action sprinklers all use pressurized air. In wet pipe sprinklers in the pipes ensures the water is delivered quickly.

In dry pipe and pre-action sprinkler systems, pressurized air is used to fill the pipes instead of water filling the pipes. When the air is released, because of detected fire, the water then flows through the pipe

Maintenance of firewater sprinkler system

The fire sprinkler system should be inspected periodically according to NFPA 25. Periods selected for different parts of the system is as follows:

- All gauges of firewater system should be inspected weekly or monthly.

- Alarm devices and controls valve should be inspected quaterly.

- Bracing, pipes, fittings and other signage should be inspected annually.

- An internal inspection of whole fire water sprinkler syste should be done in every 05 year.

- Test of mechnical devices should happen quaterly.

- Devices with switch type operation should be tested every 06 months.

- Every year, full testing and tagging of water flow, fire pump, antifreeze concentration, and alarm test should be done.

Quartzoid bulb detector

Quartzoid bulb detector is an important part of the sprinkler head. This burst when the temperature increases beyond the limit and water start flowing from the sprinkler head.

These quartzoid bulb detectors are color-coded like Red, Yellow, Green, orange, etc. Every color indicates different activation temperatures like:

| Color Code | Activation Temperature (°C) | Activation Temperature (°F) |

|---|---|---|

| Orange | 57 | 135 |

| Red | 68 | 155 |

| Yellow | 79 | 174 |

| Green | 93 | 200 |

| Blue | 141 | 286 |

| Mauve | 182 | 360 |

| Black | 227 / 260 | 440 / 500 |

Conclusion

Fire sprinkler system is much important part of protecting any facility or Industry. One of the main part of this QBD ( Quartzoid bulb detector ) which come in 07 colours. Each colour of this indicates different temperature range of activation.

There is total 04 kind of sprinkler system: 1. Wet Pipe 2. Dry Pipe 3. Pre-action and 4. Deluge. Each type of sprinkler system has its own importance and installed as per severity of hazard.

Firewater sprinkler start to eliminate fire in 03 steps:

- Detection of heat

- Activation of sprinkler system

- Elimination of fire

As per standard a fire protection system must be always active at pressure of 2-3 bar in no fire condition. During fire pressure can be increased as per requirement with help of main pressurising pump. Jockey pump is also used to maintain any loss of pressure because of piping fitting and head loss.

Sprinkler system need to check, verify and maintain periodically to avoid any unwanted incident. Each part of sprinkler system has different maintenance period which should be done accordingly.