In the world of Chemical Engineering and Chemical Processing Industries, the Absorption tower is a vital equipment for the functioning and processing of chemical or petroleum refining.

In this article about Absorption towers, we’ll check out their parts, how they work, what they do, and more. Let’s dig into absorption towers, figuring out why they’re so important and where they’re used.

Table of Contents

What is Absorption Tower?

An absorption tower, also referred to as a scrubber, is a large cylindrical vessel designed to remove a few components from a gas stream through absorption into a liquid solvent. This process is commonly employed to capture pollutants, such as sulfur dioxide (SO2), hydrogen sulfide (H2S), ammonia (NH3), or volatile organic compounds (VOCs), from industrial emissions before they are released into the atmosphere.

More to Read: What is a Prill tower in a fertilizer plant?

Components of Absorption Tower

For the effective operation of an absorption tower, several key components are integrated, each serving a specific role to ensure efficient mass transfer between the gas and liquid phases. These components include the following:

Shell: The outer structure that houses the internal components and withstands the pressure within the tower.

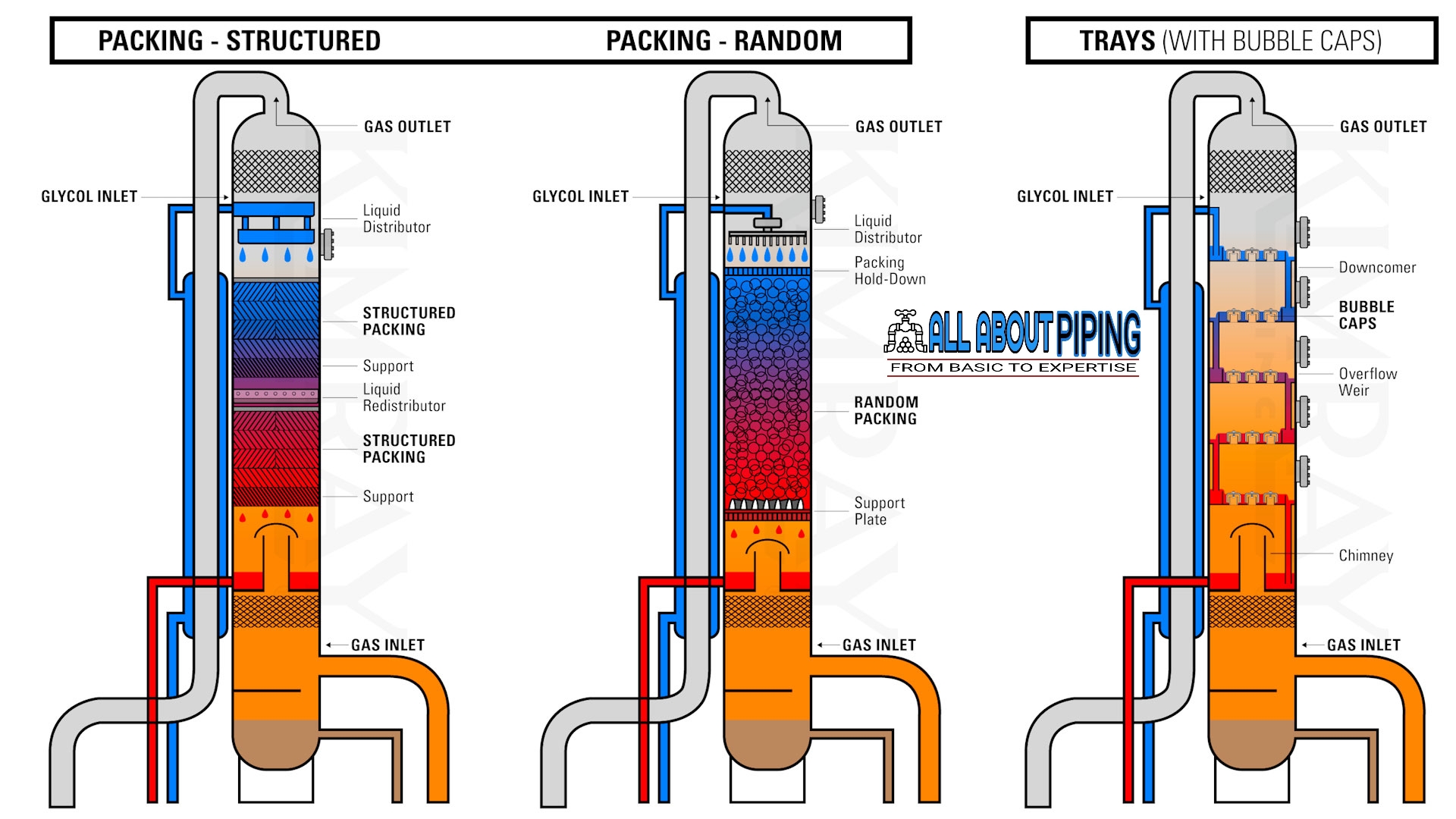

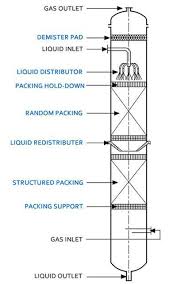

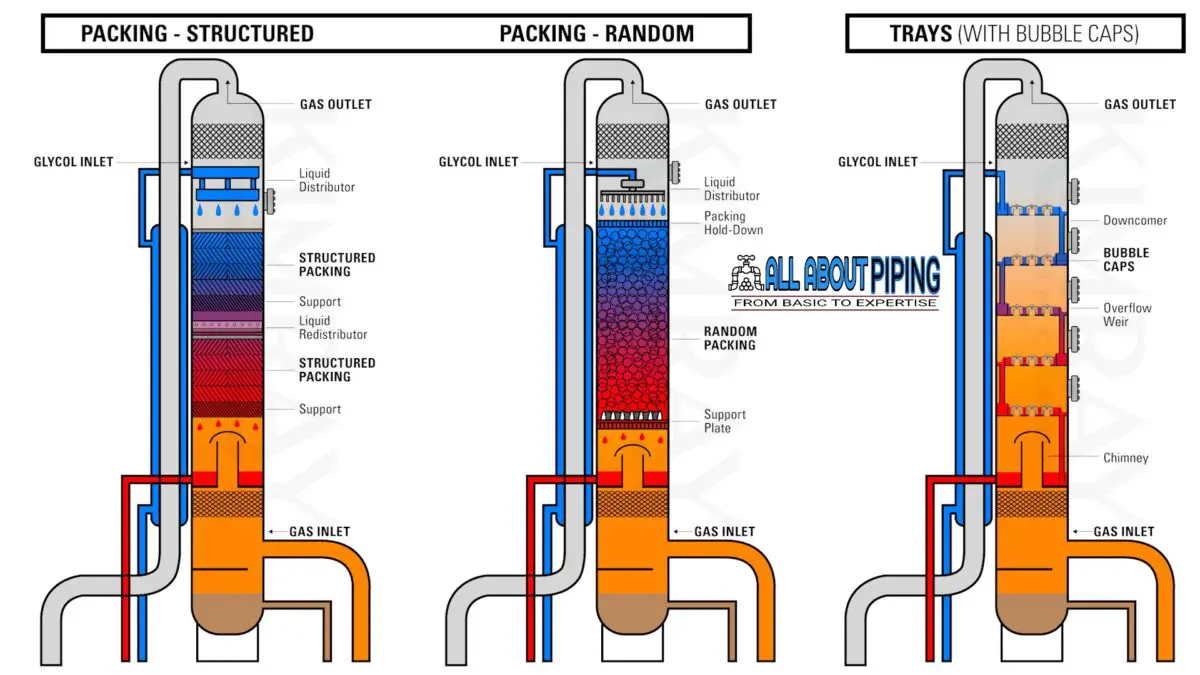

Trays or Packing Material: Internals that enhance the contact surface between the gas and the liquid, enabling efficient absorption.

Liquid Distributors: Devices that evenly distribute the liquid over the packing or trays.

Gas Inlet and Outlet: Openings for the entry of gas to be absorbed and the exit of the treated gas.

Liquid Inlet and Outlet: Points where the absorbing liquid enters and leaves the system.

Demister Pad: A component that removes entrained liquid droplets from the gas stream before it exits the tower.

| Sl. No. | Component | Function |

|---|---|---|

| 1 | Tower Shell | Holds internals, gas, and liquid |

| 2 | Packing/Trays | Provide contact surface for gas-liquid mass transfer |

| 3 | Liquid Distributor | Ensures uniform distribution of liquid over packing |

| 4 | Redistributor | Re-spreads liquid in tall towers |

| 5 | Gas Inlet Distributor | Introduces and distributes gas evenly |

| 6 | Liquid Outlet | Collects absorbed liquid at bottom |

| 7 | Gas Outlet | Releases treated gas |

| 8 | Demister Pad | Removes liquid mist from gas |

| 9 | Support Grids | Support packing and ensure free flow |

Working Principle of Absorption tower

The working principle of an absorption tower is based on mass transfer, where a gas mixture is passed through the tower, contacting a liquid that selectively absorbs one or more of the gas components. The gas is introduced from the bottom and rises through the tower, while the liquid flows downward. The trays or packing material provide a large surface area for gas-liquid interaction, facilitating the absorption of specific gases into the liquid phase. The remaining gases exit from the top of the tower, while the liquid leaves from the bottom, now containing the absorbed components.

More Resources: Falling film evaporator: Design, Working, Features and Application

Features of Absorption Tower

Some of the important features of Absorption tower which makes it an important equipment of Chemical industries as follows:

- Vertical design for optimal gas-liquid contact.

- Large Surface Are through trays or packing to enhance absorption efficiency.

- High adaptablity for any type of chemical processes.

- Adjustable internal for different flow rates and absorption requirements.

- Counter-current flow is the most common and effective configuration, where the fresh absorbent liquid enters from the top, and the gas enters from the bottom.

- Designed to handle a wide range of operating conditions, from ambient to high pressures and temperatures, depending on the application and absorbent used.

Factors affecting the Efficiency of Absorption tower

The efficiency of an absorption tower depends on how well the gas and liquid phases interact to allow the desired component(s) in the gas to dissolve into the liquid. Several operational, design, and physical parameters influence this process.

- Gas-Liquid Contact Area: The efficiency of absorption increases with a larger contact surface between the gas and liquid phases, as it promotes better mass transfer throughout the column.

- Flow Rates of Gas and Ammonia: The relative flow rates of gas and liquid—commonly expressed as the liquid-to-gas ratio—play a critical role, as imbalanced flow can lead to either inadequate absorption or operational issues like flooding.

- Nature of Absorbent (Solvent): The chemical and physical properties of the absorbent, such as solubility and reactivity with the gas component, directly influence how effectively the gas is captured during its passage through the tower.

- Temperature and Pressure: Operating temperature and pressure affect gas solubility in the liquid, with higher pressures and lower temperatures generally enhancing absorption, especially for physical absorption systems.

- Tower Internals and Design: The type and arrangement of internals, such as packing or trays, along with column height and diameter, determine how well the gas and liquid phases interact during the process.

- Distribution Uniformity: Uniform distribution of both gas and liquid across the cross-section of the tower ensures consistent contact and prevents inefficient zones, which could otherwise reduce performance.

- Mass Transfer Coefficients: The rate of absorption is influenced by mass transfer coefficients, which are determined by the flow conditions and the physical properties of the gas and liquid involved.

- Presence of Non-Absorbable Gases: Non-absorbable or inert gases in the gas stream dilute the concentration of the target component, thereby reducing the driving force for absorption and lowering overall efficiency.

- Foaming and Entrainment: Foaming during absorption can block flow paths and decrease contact efficiency, while entrainment can lead to solvent loss and contamination of the outlet gas.

- Fouling and Corrosion: Accumulation of solid deposits and corrosion of internal parts degrade the effectiveness of the tower by obstructing flow and reducing the active surface area for mass transfer.

- pH and Chemical Composition: In systems where chemical absorption occurs, the pH and chemical balance of the liquid phase must be maintained within a specific range to ensure optimal absorption capacity and prevent unwanted reactions.

More to Read: Project commissioning procedure: 08 essential steps of project commissioning

Common Application of Absorption Tower

Absorption towers are employed in a variety of industries to perform gas scrubbing, pollutant removal, and product recovery. Some common applications include:

- Flue Gas Desulfurization: In coal-fired power plants, absorption towers are used to remove sulfur dioxide (SO2) from flue gas, helping reduce acid rain and meet environmental regulations.

- Ammonia Recovery: In the fertilizer industry, ammonia absorption towers recover excess ammonia from process gases, ensuring efficient production and reducing emissions.

- Carbon Dioxide Removal: In natural gas processing, absorption towers are used to remove CO2 from raw natural gas, making it suitable for pipeline transmission or liquefaction.

- Hydrogen Sulfide Scrubbing: Refineries and gas plants use absorption towers to remove toxic hydrogen sulfide (H2S) from gases before further processing or release into the atmosphere.

- Air Pollution Control: In industries that emit hazardous gases, absorption towers help scrub harmful pollutants from the exhaust gases before they are released into the environment.

Benefits of Using Absorption Tower

The primary benefits of using an absorption tower in industrial processes include:

- Efficient Removal of Contaminants: Absorption towers can effectively remove unwanted gases from a gas stream, making them vital in reducing pollutants and improving product quality.

- Continuous Operation: Absorption towers are designed for long-term, continuous operation with minimal downtime. This makes them cost-effective for high-throughput processes.

- Environmental Compliance: By capturing harmful gases like SO2, H2S, and CO2, absorption towers help industries meet stringent environmental regulations and reduce their overall carbon footprint.

- Flexibility in Applications: Absorption towers can handle a wide range of gas and liquid compositions, making them versatile in various industries, from chemicals to oil and gas.

- Cost Savings: In some cases, absorption towers recover valuable gases, providing economic benefits through product recovery in industries like ammonia production or natural gas processing.

Disadvantage of using Absorption Tower

Despite their numerous advantages, absorption towers also have some limitations:

- High Operational Costs: The costs associated with maintaining and operating an absorption tower, particularly energy and solvent costs, can be high. In processes where large volumes of gas are treated, this can be a significant expense.

- Maintenance Requirements: Regular maintenance, including cleaning, inspection, and replacement of internals like packing or trays, is essential to prevent fouling or corrosion. This can lead to operational downtime and added costs.

- Limited to Soluble Gases: Absorption towers are only effective for gases that are sufficiently soluble in the chosen liquid. In cases where gases are not soluble or react poorly with the liquid, other separation methods may be required.

Cleaning and Maintenance of Absorption tower

Absorption towers require regular cleaning and maintenance to operate efficiently. Key practices include:

- Periodic Inspections: Regular inspections of the tower’s internals, including trays, packing, and support grids, help identify potential issues like fouling, corrosion, or mechanical damage.

- Internal Cleaning: Over time, debris, contaminants, and fouling materials can accumulate within the tower, especially in the packing material. Regular cleaning ensures that the gas-liquid interaction remains effective.

- Replacement of Components: Packing material, trays, and demister pads may wear out over time and need to be replaced to maintain the tower’s performance.

- Flow Monitoring: Monitoring gas and liquid flow rates ensures that the tower operates within its design parameters, preventing issues like flooding or weeping that can degrade performance.

Difference between absorption and stripping in Absorption tower

While absorption and stripping processes are often discussed together, they serve opposite purposes:

- Absorption: This process involves removing specific components from a gas stream by dissolving them in a liquid. It is used to purify gases or recover specific components. In an absorption tower, the gas flows upwards, and the liquid flows downwards, enabling the transfer of gas into the liquid phase.

- Stripping: In contrast, stripping involves removing dissolved components from a liquid by introducing a stripping gas. The gas strips out the absorbed components from the liquid, making it possible to regenerate the solvent for reuse or recover valuable gases.

| Aspect | Absorption | Stripping |

|---|---|---|

| Objective | To dissolve gas components into a liquid solvent. | To remove dissolved gases from a liquid stream. |

| Direction of Mass Transfer | From gas phase to liquid phase (gas dissolves into the liquid). | Concentration gradient of the gas between the gas and liquid phases. |

| Typical Flow Setup | Gas enters from the bottom, liquid enters from the top (countercurrent). | Liquid enters from the top, stripping gas enters from the bottom (countercurrent). |

| Main Driving Force | Concentration gradient of the gas between the liquid and gas phases. | Flue gas desulfurization, natural gas purification, and environmental control. |

| Common Gases Removed | CO2, H2S, NH3, SO2, etc., are absorbed into liquids like water, amine solutions, or alkaline solutions. | Ammonia, volatile organic compounds (VOCs), and light hydrocarbons are stripped from liquids. |

| Common Applications | Water treatment, solvent recovery, and petroleum refining. | Water treatment, solvent recovery, petroleum refining. |

Conclusion

Absorption towers play a critical role in various industrial processes, enabling efficient gas-liquid interactions for the removal or recovery of specific gases. Understanding the principles of absorption and stripping, along with the components and working mechanisms of these towers, is essential for optimizing performance and efficiency. While absorption focuses on capturing gases into a liquid, stripping is used to remove gases from liquids, and both processes are often employed together for greater operational effectiveness. By ensuring proper design, maintenance, and understanding of performance parameters, absorption towers can deliver significant environmental and economic benefits, though they also come with certain challenges, such as operational complexity and maintenance requirements. With their wide applications across industries like power generation, natural gas processing, and water treatment, absorption towers remain indispensable in both industrial and environmental management contexts.