There are many valves of the Quarter turn family group, a Butterfly valve is one of them. Quarter turn valves are those type of valve which allows or restrict the flow of fluid with 90º disc or ball movement. A triple offset butterfly valve is the highest level of the valve and a kind of high-performance butterfly valve in valve industries that can effectively work in high pressure and temperature.

Triple offset butterfly valve one of its kind in the group of valve family. this can work efficiently in high pressure and temperature with absolutely no leakage. This type of butterfly valve has metal to metal sealing arrangement that makes it efficient for sustaining in critical conditions.

In this article, we will focus to give you detailed information about the Triple offset Butterfly valve. Through this article, we will try to expand your learning on a special type of butterfly valve, i.e. Triple offset butterfly valve. Here you will learn:

- What is a butterfly valve and why it is named so?

- What is a triple offset butterfly valve?

- How triple offset butterfly valve is different from other types of butterfly valves?

- Design details of a triple offset butterfly valve

- Use and Advantages of a triple offset butterfly valve

More to Read: What is the Role of a valve in Piping? Type of Valves in Piping.

Table of Contents

What is Butterfly Valve?

Just like the name of a ball valve because of its shape, The butterfly valve got its name because of its movement of the disc during the action of controlling the fluid flow seems like the wings of a Butterfly.

To know well what is a triple offset butterfly valve, you first have to know about the structure, working, and operation of a normal butterfly valve. A butterfly valve is a quarter-turn rotational motion valve that can be used to isolate, regulate and inaugurate flow in the piping system. A 90º rotation of the valve handle provided quick and complete operation of the valve disc.

The butterfly valve body with less width, Round disc, metal to metal or soft seat material sealing surfaces, top & bottom shaft bearing, and packing circular box to accommodate all components. Generally, a butterfly valve has a disc positioned in the center of the connected piping flanges and a stem that is connected to the handle via a gearbox arrangement outside the valve.

In the closed position of the valve, the disc remains perpendicular to the flow and sealed by the valve seat either made of metal or non-metallic seat. When Handle turns in 90 degrees the disc of the valve moves apart from the valve seat and positions itself in parallel to the flow direction. We can also partially open the butterfly valve to throttle flow.

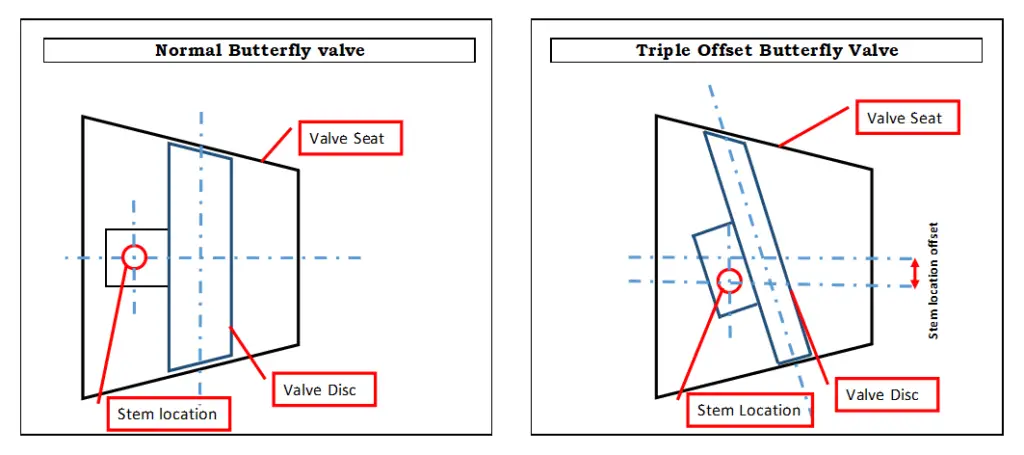

The stem connected to the disc of the valve passes through the center of the pipe bore and seat. This means the vertical center of the stem and the disc lies on the same plane. While moving the stem with the handle disc of the butterfly valve Turn around the same axis.

Featured Article: What is a solenoid valve? How does the Solenoid valve work?

What is a Triple Offset Butterfly Valve?

In the oil and gas industry, A triple offset butterfly valve has its optimum role where a vacuum seal is required in high-temperature conditions. A triple offset butterfly valve has three separate offsets from the center that makes it special.

Because of those three offsets in the valve design, this is called a Triple offset butterfly valve or triple eccentric valve or TOBV. In the case of a butterfly valve. Apart from TOBV, There are two more types of design with respect to the stem, disc, and seat connection.

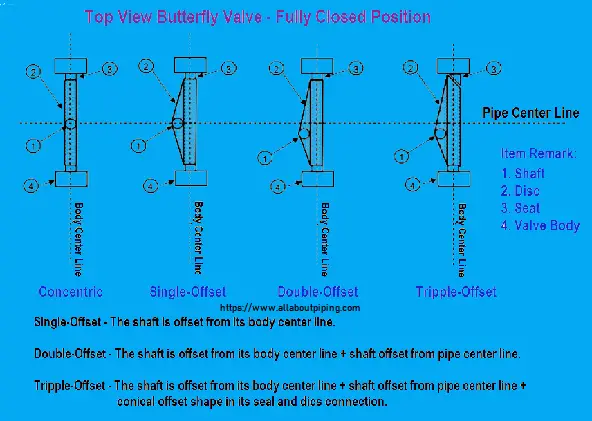

Zero offset Butterfly valve

In this type of design disc of the valve rotates around the center axis of the valve stem that providing a 360-degree rotation of the valve disc. Here sealing is achieved by deforming the disc with soft seal material like PTFE resulting in full friction with the sealant through the full operating lifetime.

Single offset Butterfly valve

In this type of butterfly valve shaft of the valve is designed to offset from the centerline of the valve body.

Double offset Butterfly Valve

To reduce the friction between seat and disc and allow displacement of the seat, the shaft is offset from the centerline of the disc seat. This arrangement creates a cam action that helps to provide a lift of the disc from the seat resulting reduction in friction

Double offset vs Triple offset butterfly valve

The main difference between double offset and triple offset valve is as tabulated below:

Difference between Double offset and Triple offset butterfly valve

| Description | Double Offset Butterfly Valve | Triple Offset Butterfly Valve |

|---|---|---|

| No. of offset Axis | 02 | 03 |

| Seat Material | Soft Material | Metal Seat |

| Sensitivity to Pressure and Temperature Fluctuations | Yes | No |

| Seat Friction | Low | Very Low |

| Applications | Process On/Off Throttling | Critical and Severe Applications |

| Seat Lifetime | Long | Very Long |

| Fluide Services | Clean | Dirty |

| Bubble Tight Off | Yes | Yes |

| Pressure Drop | Highest | High |

| Cost | Moderate | High |

Design and working of Triple offset Butterfly valve

A triple offset butterfly valve is also known as a triple eccentric valve. A triple offset butterfly valve is the prime isolation valve for operation in a vacuum to the high-pressure piping system, Particularly where absolute zero leakage is a must. The design of the Triple offset butterfly valve makes it non-rubbing, non-jamming, metal to metal sealing, and highly efficient in high pressure and temperature. This type of valve because of its highly precise design provides zero leakage and bi-directional operational functionality.

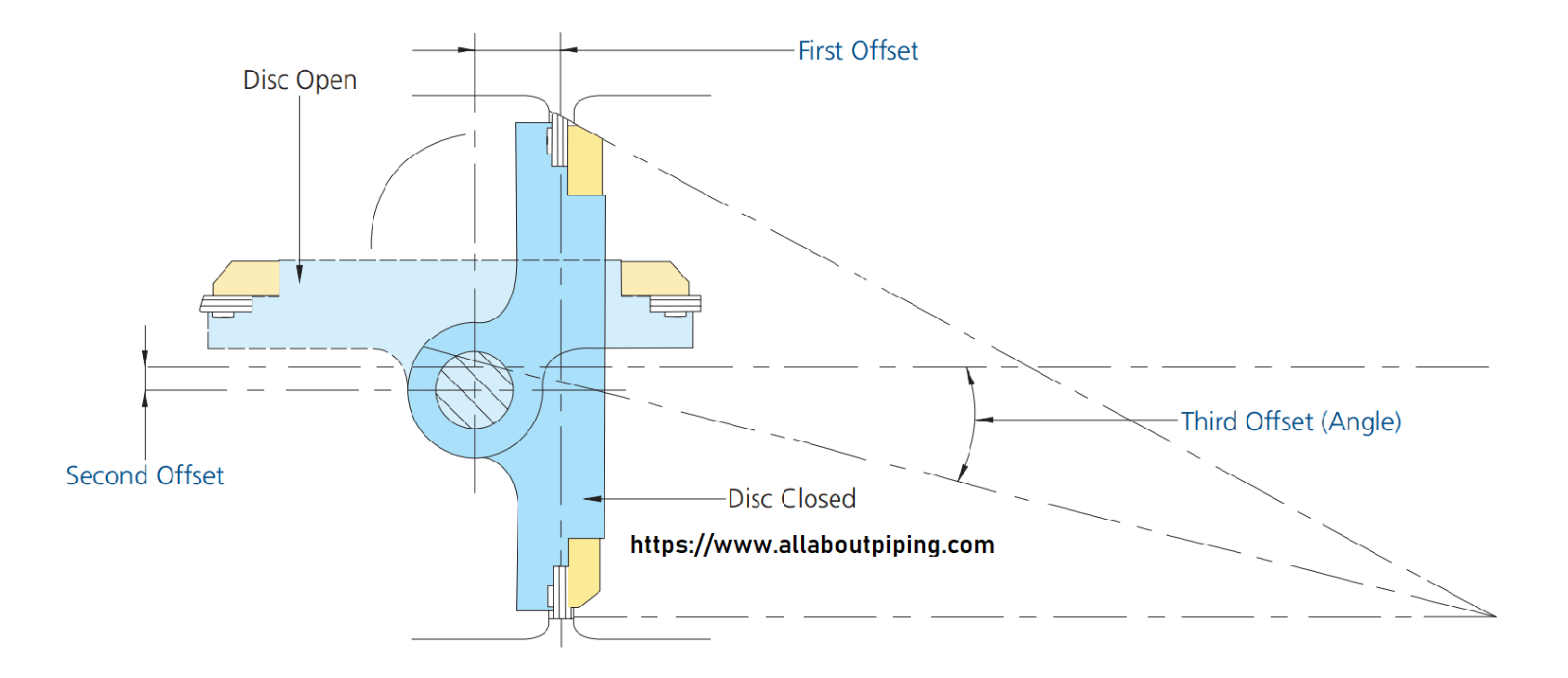

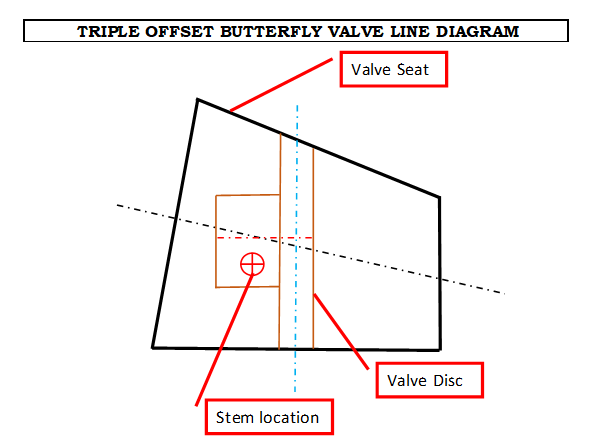

A triple offset valve is the highly precise design of a butterfly valve. It is called a triple offset butterfly valve because of offset in the three-axis during movement of the valve disc.

1. Center Line of Valve disc is not Perpendicular to Centerline of the valve disc. This is the first offset.

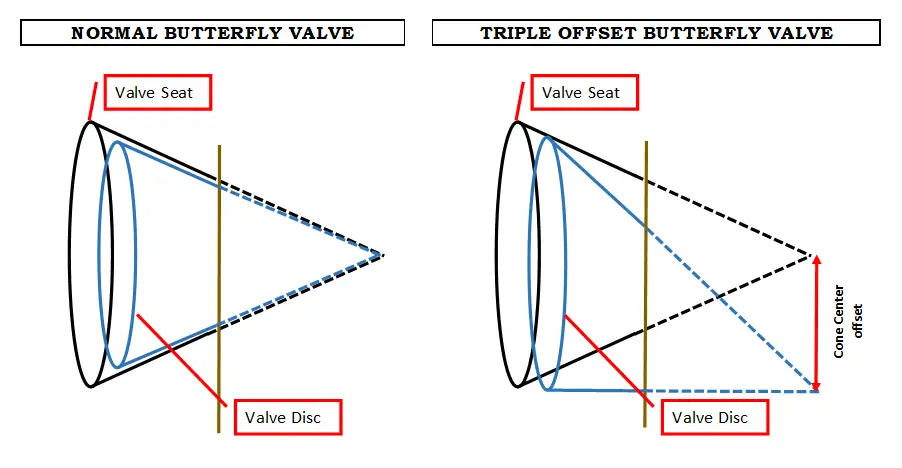

2. Imaginary cone forming Valve disc and Valve seat don’t have the same centerline. There is some offset between the centerline of both cones. This is the second offset.

3. In the Normal butterfly valve location stem shares the same centerline as of valve disc. In the case of the Triple offset butterfly valve, the valve stem has an offset from the centerline. This is the third offset.

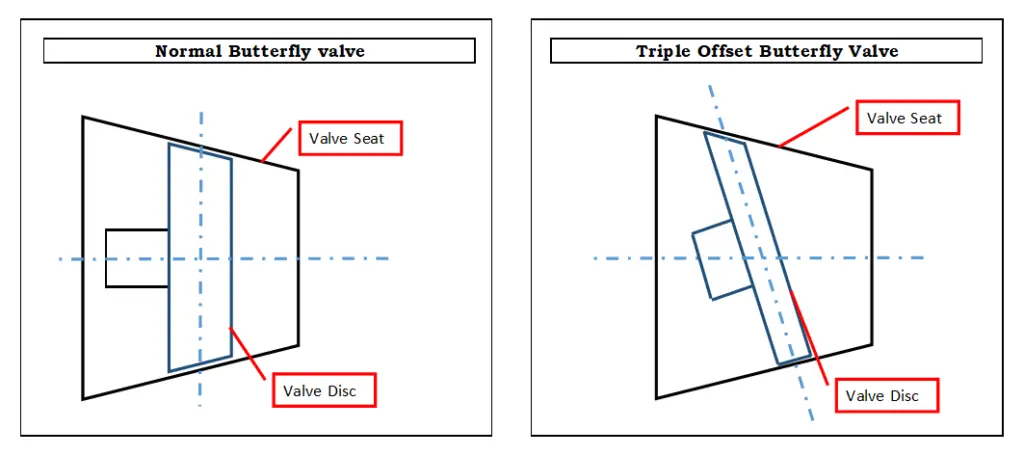

Combining all those three offsets of the valve the final shape of the disc and seat looks like:

Benefits of Triple offset design

Apart from being more efficient in high pressure and temperature, the triple offset design of the butterfly valve provides much more benefits like:

- Cam-action of the valve because of offset in valve stem location ensures the metal component never touches each other until it’s completely close.

- Very little contact between valve disc and valve seat results in repeatable sealing and a tremendous increase in valve life.

- Metal to metal sealing arrangement ensures bubble-tight shut-off with absolute zero leakage.

- There is no cavity between sealing components because of that no clogging is there and also valve requires low maintenance with extended valve life.

- Because of its geometry, sealing components provides friction-free touch with the valve seat.

- TOBVs construction doesn’t include any material that is typically affected by corrosion.

Code and Standard for Triple Offset Butterfly Valve

The triple offset butterfly valve is designed on a basis and in accordance with international standards.

| Triple offset Butterfly Valve Codes and Standard | |||

| Parameter | Standard | ||

| Design | API 609 (Category B), | ||

| ASME B16.34 | |||

| Ends Type | Wafer/ Wafer Lugged | Face-to-face | API 609 |

| End Flange Dimensions | ASME B16.5 | ||

| Flanged | Face-to-face | API 609/ ISO 5752 Ser. 13/ | |

| Ser. 14/ Ser. 8 | |||

| End Flange Dimensions | ASME B16.5/ ASME B16.47 | ||

| Butt-weld | End-to-end | ASME B16.10 | |

| End Dimensions | ASME B16.25 | ||

| Testing | API 598 | ||

| Pressure – Temperature Rating | ASME B16.34 |

Triple offset Butterfly Valve vs. Normal Butterfly Valve

The major difference between normal butterfly valves and triple offset butterfly valves are as follows:

Difference between Triple offset Butterfly Valve and Normal Butterfly Valve

| Sl. No. | Normal Butterfly valve | Triple offset butterfly valve |

|---|---|---|

| 01 | This can't perform in high temperature and pressure environment | This can perform efficiently in high temperature and pressure environment |

| 02 | This type of valve has softer material of sealing arrangement | TOBVs have metal to metal sealing arrangement |

| 03 | There is friction between valve seat to valve disc | No friction at all between valve disc and valve seat |

| 04 | Low performing sealing action | High performing sealing action |

| 05 | can't be used in vacuum piping system | works well in vacuum piping system |

| 06 | Respectively Short life expectancy | Respectively long life expectancy |

| 07 | Time to time maintenance required | Very less maintenance is required |

| 08 | Cam action not available with non-offset valves | Offset in stem design provides cam action to life disc immediately from seat |

| 09 | cavity and clogging | No cavity or clogging |

Use of Triple offset butterfly valve

The use of a triple offset butterfly valve is much diversified and helps in all industries.

- refining and petrochemical process

- hydrocarbon processing

- Hydrogen

- Oxygen plants

- refrigerant fluids system

- Thermal fluids System

- Hot gases

- Flare gas

- Vaccum services and piping systems

Conclusion

TOBVs are much efficient and durable in high pressure and temperature condition with many effective sealing features. Its offset design and technology make it long-lasting with low maintenance. You can refer to this video below to understand more about the design of the triple offset butterfly valve.