In the industries like pulp and paper flowing fluid inside pipes is very thick. The normal valve will not be able to accurately stop the flow and there was always some leakage. Knife gate valve is introduced to the world to solve these issues in industries working with high viscous fluid.

This is a specially designed valve to operate in a piping system that deals with dense and sticky fluid. Knife gate valve was first introduced in 1927 and since then it is widely used all over the world. In this article we will get aware of:

- What is knife gate valve and how this works?

- Parts of knife gate valve

- Application and features

- Types of KGV

- Benefits of KGVs

More to Read: What is the Role of the valve in Piping? Type of Valves in Piping.

Table of Contents

What is Knife gate valve?

A knife gate valve is a kind of shut-off valve. This is used to start and stop the flow in the piping. It is mainly used in a piping system that carries gas or liquid. Specially piping system in which high dense material flows.

The gate of a knife gate valve is built with sharp edges to cut through high dense material flowing in the pipe. To stop the flow when required this valve uses the pressure drop function. This ensures that the valve is perfectly sealed and no leakage is there.

Knife-shaped gate of knife gate valve Cuts through the tough or sticky material. It also ensures that any excess material is not being stuck between the valve components. This also insure that excess material will not create any cleanliness issues.

More Resources: What is a solenoid valve? How does the Solenoid valve work?

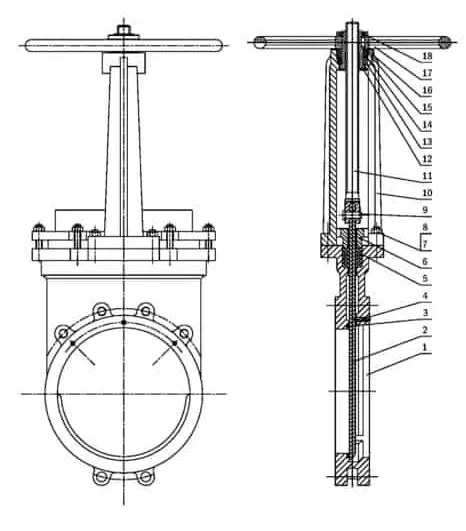

Parts of Knife Gate valve

Like every other valve, there are some common components that are included in the valve to make this operational.

- Body

- Wedge

- Seat

- Stud

- Packing

- Gland flange

- Nut

- Stud

- Pin

- Yoke

- Stem

- Stem nut

- Bearing

- Gland nut

- Pin

- Key

- Hanwheel

- Locknut

From the above-mentioned parts there are few main parts of the valve are described as follows:

- The Gate: This is one of the main components in all type of gate valve. But in case of Knife gate valve it is specially made like knife for stopping high viscous and sticky fluid. This always made of stainless steel to withstand corrosion.

- Valve Body: Body of KGVs are generally made of industrial grade carbon steel and it may vary according to requirement and environmental condition.

- Valve seat: This is part of valve where gate rests when valve is closed. The seat of the valve is mostly made from stainless steel to withstand and resist corrosion. It is also madeup of PVC or plastic for smaller size of valves. This part of valve ensure that there is no leakage through the valve.

- Stem: This basically the shaft of the valve that is attached to the gate and hand wheel. When hand wheel is rotated this helps the gate to move up or down.

- Hand wheel: This helps the to operate. By turning it, Knife gate valve becomes able to stop or start the flow of fluid. This can also be replaced with an electric motor or hydraulic operation to make valve operation remotely.

More Resources: What is Triple Offset Butterfly Valve? Definition, Design, Application, Code, and standard

Classification of Knife gate valve

KGVs are classified 04 categories according to their structure and material type:

- By Bode material

- Carbon steel KGVs

- Stainless steel KGVs

- Lines Valves

- By Connection Types

- Wafer type

- Lug type

- Flanged

- By sealing method

- Metal seated

- Resilient seated

- By stem Type

- Rising stem

- Non Rising stem

How does Knife gate Valve Works?

A knife gate valve has a component that is equipped with a blade to cut through high dense fluid clogging in the pipe. This type of valve is created to function in the most corrosive and abrasive conditions of industrial processes.

These valves have low-pressure constraints and are intended to seat the blade into an elastomer when the valve is closed. During its closing process knife of the valve cut the substance being handled in the pipe. When some solid mass or powder passes through the knife gate valve this accumulates on the seat of the valve that makes the valve fail from tight closing. In this case, the must be replaced

Type of Knife gate valve

There are 03 types of Knife gate valves available in the market:

- Hopper Shape knife gate valve

- Wafer type knife gate valve

- Through conduit knife gate valve

You will get to learn about these types of valves in a further section in details

Hopper Shape Knife gate valve

This type of KGVs is unidirectional by design. These are built for bulk handling services applications. The special design of the body allows for easy pass of the fluid and makes it ideal to use as a silo outlet valve. This valve is widely used in industries like:

- Power plant

- Food and beverage

- Chemical Plants

- Mining

These valves are normally installed in the reverse position “i.e. Seat in upstream direction” to avoid problems like build-up in the valve body, seat wear, and difficult closing.

Wafer Knife Gate Valve

This type of knife gate valve is has a gate specially designed to operate in bi-direction. Gate installed in this type of KGV is sandwiched between its flanged connections. This design ensures the non-clogging of the valve during shut-off. Some of the features of these valves are:

- Bidirectional knife gate valve with “wafer” design.

- Two‐piece cast body, joined by screws, with internal guides for smooth movement of gate.

- Provides high flow rates with low-pressure drops.

Industries, where wafer type knife gate valve is frequently used, are:

- Waste water treatment plant.

- Bulk viscous fluid handling

- Power plant

- Mining

- Chemical plants

Through conduit knife gate valve

In this type, the seat of the valve is replaced with two body seats and a top and bottom packing gland. These seats seal the valve when it’s in a fully closed position. This valve has high through leakage and fugitive emission.

This valve typically works well with fluids that contain high fiber. There has also been a success in mineral processing plants, with high scale because the scale actually helps the valve seal completely.

Features of knife gate valve

Some of the main features of Knife gate valves are as follows:

- Unibody design and rugged heavy duty construction ensures long valve life and greater reliability

- Flexible two-piece sleeve system allows valve to cycle in heavy slurries without sticking

- Sleeves are easily replaced without disassembling the valve

- Replaceable upper seal design is not only packingless, which eliminates the need for periodic adjustment, it is also a self-lubricating system and is rechargeable without valve disassembly (sizes 2” through 16”)

- Full port design reduces pressure drop and turbulence

- Open bottom allows for the purging of large solids and solids in high concentration

- Bi-directional shutoff

- Wafer style saves pipeline space

- Sleeves are available in a variety of materials to handle abrasion and chemical applications

- Flushing plate option allows for periodic cleaning of the lower discharge vent and allows flushing as needed

- Enclosed bronze stem bushing with a protected grease chamber means less operating force after long dormant periods

- Upper stem protector and optional protective lower stem cover prevent external contamination

Use of Knife gate valve

Because of their specialty to handle thick liquids, knife gate valves are highly demandable in industries that deal with the viscous material. These valves are specifically used for that application that deals with hard-to-clean material. For Industries where knife gate valves are used are as follows:

- Mining and mineral processing

- Waster water processing

- Pulp and Paper

- Steel manufacturing

- Slurry transportation

- Food and beverage

- Heavy oil transportation

- Processing units of non-flammable viscous fluids

- Sand and gravel plants

Benefits of Knife gate valve

- When Full open Knife gate valve provides a very low and smooth transition for flow.

- Here Flow can be in both directions.

- The valve can be installed in any position. However, it is preferable that the stem is perpendicular to the ground and the flywheel on top.

- Shorter valve length, even for large nominal diameters of pipe.

- Economically and conveniently available all over the world.

- There are types suitable for high pressures.

- Easy to maintain.

Difference between Knife gate valve and gate valve

- The main difference is the type of application or media these valves handle. Knife gate valves can handle slurries, powder, or thick fluids more efficiently than gate valves. While in the case of a gate valve, It requires clean fluid to function properly.

- Another difference between those valves is that the Gate valves are designed according to ANSI standards while the Knife gate valves are designed according to TAPPI standards.

- Gate valves are bi-directional, extensively used in fluid applications, and only have metal seating. While in case of KGVs seating materials can be made of PVC, Plastic or Metal.

- The difference in packing gland of valve is also a distinction. In case of Gate valve V-ring packing seals the shaft that is connected to gate while in KGVs Gland seals around the gate.

Conclusion

In the Industries where high dense and high viscous fluid is processing, the Normal-type of valve won’t be useful as it will clog the valve and perfect sealing won’t happen. To avoid this issue knife gate valves are invented in 1927 in Sweden.