It is always interesting to see your project visually represented for first time on drawings. Its an exciting feeling with inspiring timing. This is the first time to observer your ideas and hard work to get to take its shape.

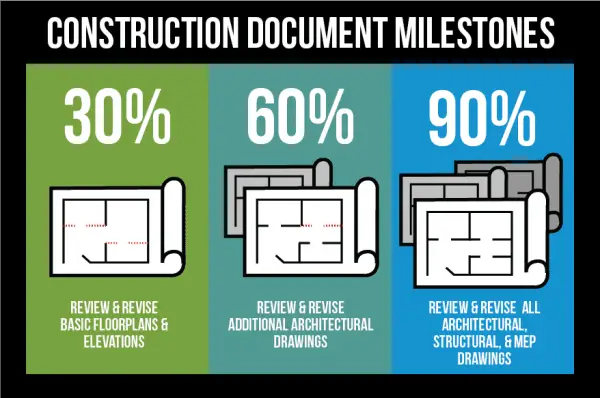

For projects, Design team follow the 30-60-90 issued for construction approach of a under developing model and share its project drawings. In this article we will describe about:

- What is a 3D model?

- Purpose of pre-designing.

- 30%, 60%, 90% model review stages, its objectives and Points included in these.

- Supporting document requirement for model review meeting.

- Participant and responsibility of 3D model review meeting

Feature Post: Design of Piping System: A small brief

Table of Contents

What is 3D model?

A 3D model is a graphical representation of all the items like equipment, piping, instruments, electrical connection on its planned designed location in a three-dimensional view.

3D models are used to portray real-world and conceptual visuals in a simulation through drafting software to navigate the real interpretation of drawing and physical look and positioning of components of some plant.

Purpose of Pre-designing

A plant is first drafted in a 3D model and pre-designed to fulfill the following purpose:

- To select a preffered and more efficient alternative for the project.

- For developement and set of project goals.

- Developing design criteria according to requirement.

- Looking for some alternative analysis.

- To identify potential hazards and risks.

- For developing a conceptual planning with cost estimation.

- Idetify stakeholder and to make some individual responsible for some specific work.

- To identify required regulatory necessity.

- for determination of NEPA/SEPA guidelines.

More Resources: What is Cryogenic Piping? A brief on Piping material, Insulation, Pipe Sizing, and Hazards.

30% model Review

From the 03 basic stages of model review milestone, 30% model review generates a basis for plant layout, its accessibility, and Safety measures recommendation. This is the 1st milestone for model preparation, After which contractor and client meet to set a basis for further development of the design.

While the specifics of submission vary for each project. The overall 30% of design documents are much universal. This phase aims to lay out the major design elements of the project and establish a cost and timeline of the project.

Along with the drawings, the project scope, schedule and budget will be fine-tuned in this stage. The project manager has to develop and commit a baseline schedule, baseline budget, and baseline cost estimate.

During the 30% model review phase, the project team will have the opportunity to review the basic line. It is easier to look critically at the project without getting into the trap of details.

Overall, the 30% model design phase is the foundation of the project upon which the project team will go further. And will develop more carefully with time by analyzing drawings and providing thoughtful feedback to develop design continuously

Objectives of 30% model review

The main objective of the 30% model review are as follows:

- To agree on overall layout of the plant that meets base hazard reccomendation and other requirement of project.

- To freeze the equipment location as per available information.

- TO identify primary operational/Assessable/Maintenance points or platforms.

- To identify Improvement/modification to meet the predominantly the safety and operation aspects.

- To release foundation loads.

- To decide for nozzle orientation information to vendor.

- Release of main underground isometrics for fabrication.

More Resources: Piping Supports: Types, Codes, Design, Selection, Working, Installation

Things included in 30% model

During the 30% model review meeting there are many points to be included in terms of safety, Mechanical, Piping, Civil, Electrical, and Instrumentations.

Points to include in Safety

- Safety egrees route.

- Primary defined escape route and markup.

- Safety distance between equipment.

- HAZID comments.

- Safe location identification for flare, vents, and exhaust.

- Arrangement of plant to optimize maintenance requirements.

- Overall plant layout

Point to Include in Structural

- All primary and secondary steel framing

- Intermidiate frame and platforms

- Main assess stairs

- Architectural item including shelter /Store/Technical building/blast wall/workshop or equipment rooms.

- Major Piperacks

Points to include in Mechanical

- Location of all major process and equipment location.

- Crane reach and crane positions

- Monorail and davits

- Location and orientation of all equipments and other space taking items.

- Package unit location and orientation

- Primary operating plateforms for valves, equipments and Maintenance.

- Designated layout area for chemical/Catalyst loading requirements.

Points for Piping

- All major big bore process critical lines and utility lines.

Points to Include for Electrical/Instruments

- Major Electrical equipments

- Preliminary main electrical and instrumentaion cable tray routes

- Location and volume of electrical and control rooms.

Points to include for Civil

- Main and secondary access road layout, including road crossing structures and culvert.

- Crane access for Construction and Maintenance purpose.

- Infrastructures like Administrative building, Laboratory, Central control room, electrical room, Warehouse, maintenance shop etc.

- Pipe rack and pipeway lauout.

- Location of interceptors and effuluent treatment facilities.

- Equipment support, Foundation and pedestals.

60% model Review

2nd milestone of model review is 60% model design development. Here all the doubt of 30% model review must be cleared and discussion and doubt clarification has been done from the further development till 60% design.

Once the revision according to review during the 30% design phase has been updated project team will issue the next review meeting. i.e. 60% model/design review.

During this round, the project team will focus on analysis on constructability, budget consideration and modification, and potential issues or concerns. The team will discuss the constructability of the drawings and any preferred equipment and material needed to build the project during this stage.

60% model review phase is a good time for Value engineering because the impact on schedule and overall design is minimum. As value engineering afterward can be costly and time-consuming once the project is scheduled and in motion.

Objectives of 60% model review

With clarification of 30% model review doubt, 60% model has purpose and objectives:

- To identify if any layout modifications have impact on the safety philosophies and requirements as previously agreed in the 30 % Model review.

- To review the location of secondary fire / safety equipment

- To identify if the location of the Main Equipment has been updated

- To review the location of Minor equipment.

- To review the secondary Operability / Accessibility / Maintainability to the different areas.

- To Identify Improvements / Modifications to meet the requirement of the project, mainly the safety operational aspect.

- Review and release of UG isometric for IFC.

- Release of nozzle orientation information to vendor.

Things included in 60% model

As for the 30% model review, Things to be included for the 60% model review are categorized in the same way as Safety, Structural, mechanical, piping, Civil, Electrical, and Instrumentations.

Safety Points to include in 60% model review

- Safety egress routing as 30%model review comment and review.

- Primary escape route finalisation as per 30% model review and comment.

- Secondary escape route confirmation for all area.

- Safe distance between equipments as per previous comment and review.

- Location of Vents/Exhaust in safe area as per previous comments.

- Identification of fire hazard zone, restricted zone, Impacted area.

- Eye wash, Safety shower and other Life saving safety equipment location.

- Review for adequet access for fire fighting equipments.

Structural related points to include in 60% model review

- All primary and secondary steel framing design confiremation as per 30% model review comment.

- Design of main access and intermidiate plateform review as per previous comment.

- Review for technological building, blast wall and shelters as per previous comment.

- Assess ladders, supporting structure and handrails.

- All kind of pipe rack

Mechanical related points to include in 60% model review

- Finalization of location of all major equipment as per 30% model review.

- Mechanical Handling equipment location finalisation.

- Package unit layout and orientation finalisation as per 30% model review and comments.

- Primary equipment platform for valves, equipments, and maintenance as per previous comments.

- Secondary equipment platform for valves, equipments, and maintenance as per previous comments.

- Location of all process and utilityequipment.

Piping related points to include in 60% model review

- To freeze big bore, stress critical pipe routes.

- Review on majority of small bore line, Instrument tapping connection and location, for:

- Process Line up to 4″ NB and above.

- Utility lines from 2″ NB to 10″ NB.

- Major and general pipe support location and design.

- detailing of piping network to show all auxiliary item to include in P&ID.

- Piping network on pipe racks including expansion loops.

Electrical/Instruments related points to include in 60% model review

- Major electrical equipemt location finalization as per previous comment and review.

- Primary layout of overhead cables and main cable trasin block in eletrical rooms.

- Lighting for all location in each level of elecvation.

- Packaged equipments motors, electrical heaters and control panel location.

- Preliminary cable tray route as per previous review and comment.

- Location and volume of electrical and control room as per previous review and comment.

- Main cable tray and junction box location.

- Local control panel, local junction box and inline instrument mounting devices.

- Field instrument and stanchion according to piping instrument tap points.

- Instrument stands according to permanent accessblity of instruments.

Civil related point to include in 60% model review

- Main and secondary access road layout, incuding road crossing structure and culvert.

- Infrastructure-Administrative building, Laboratory, Central control room, Electrical room, warehouse, and Maintenance shop.

- Pipe rack and pipe layout as per 30% model review and comment.

- Location of interceptors and effluent treatment facilities.

- Equipment support, foundation, and Pedestal as per previous comments.

- Underground facilities and culvert location.

- Storm drains, catch basin, pit, and trench layout.

- Perimeter and fencing layout

More resources: Basics of Piping Project Execution Plan: A short Briefing

90% model Review

Once all comments and issues are resolved from the 60% design stage, the project design team goes for the 90% model design review. This 90% model review should include all the plans and specifications for the project.

Once everything is completed, the project team submit and call for the 90% review meeting. While this set should closely represent the final project, the modification could be required for code consideration. Additionally, the construction schedule, phasing plan, and logistics plan will be finalized.

Objectives of 90% model review

The objectives of 90% model are as follows:

- To ensure final design acceptance by the client before publication pf construction drawings and documents.

- To ensure all area of operationalblity and accessblity are accepted by client.

- To ensure construction feasiblity of all components of plant.

- To ensure all safety philosophies and reccomendation are implemented prior to publication of drawings.

- To ensure model reflects project requirements like, scope

Things included in 90% model

In general all 60% model review comment should be clarified and incorporated in 90% model review meeting. Thing to be included are categorized as follows:

Included point of Safety in 90% model review

- Final Safety egress routing plan.

- Final defined escape route.

- Final and approved safety distance between equipment.

- Frozen location of flare in a safe area.

- Final fire hazard zone/ Restricted zone/ Impacted zone.

- Final safety/Life saving equipment like eye wash and safety shower.

- Final review on access and egress of fire fighting equipment.

- Fire and gas detector location finalization.

Included point of Mechanical in 90% model review

- All process, utility and HVAC equipment.

- Mechanical handling platform and equipment.

- Detailing of equipment package of nozzle size 2″NB and below.

Included point of Piping in 90% model review

- All process piping as indicated in P&ID.

- All utility piping according to P&ID.

- All pipe supports as per design requirement.

- All under ground piping.

- All sampling connection, corrosion fittings, vent, drains.

Included point of Electrical/Instrument in 90% model review

- Secondary cable tray route to be included up to equipment termination box located in electrical room.

- Support for main and secondary cable tray

- All electrical and instrument cable trench.

Included point of Civil in 90% model review

- All main road, Secondary road, and road crossing structure, bridges and culvert.

- All infrastructure building,

- All pipe rack.

- All civil structure-Interceptor and effluent treatment plant.

- All major supporting foundation.

- All underground facilities.

- All trenches layout.

Supporting Documents and Drawings for Model Review

Prior to the model review, the following documents with their latest approved revision should be prepared and made available during the model review session. These drawings will be marked as “Model Review master“. These supporting drawings are:

- Plant and Instrumentation drawing (P&ID)

- Equipment layout

- Escape route Layout

- Equipment list

- Line list

- Previous model review action list as applicable.

- Equipment dimentional details

- Instrument Index

- Fire fighting equipment layout

- Safety equipment layout

Participants of Model Review

For model review sessions, the contractor is responsible for notifying the Client and all other disciplines about the venue and time of model review. Each Model Review session will be participated by following:

- Client Representatives

- Process: Full time involvement

- Maintenance: Full time

- Construction : Full time

- Operations: Full time

- Project Engineers: Full time

- Other Discipline: Full time/As per requirement

- Contractor Representatives

- Project Manager/ Engineers: Full time

- Model Drafting Team: Full time

- Lead Piping engineer: Full time

- Process engineer: Full time for process related clarification

- Mechanical Engineer: As per requirement

- Instrument/Electrical engineer: As per requirement

- Structural Engineer: As per requirement

- Safety engineer: Full time

- HVAC: As per requirement

- Civil Engineer: On call

Responsibilities in Model Review

3-D model review should be organized by contractor. Following some list of responsibilities to be carried out for a successful model review meeting.

| Work Activity | Responsibility |

|---|---|

| Schedule for model review | Project Manager |

| Model review document preparation | Project Engineer |

| Distribution of review document and agenda to client | Project manager/Project engineer |

| Organize model review venue | Project engineer |

| Review tools and create model file | Design Administrator |

| Report status of 3D CAD model | Lead piping engineers |

| Report of hold item list | Lead piping engineers |

| Coordination during model review meeting | Project engineer |

| Preparation and Summarize of action list | Project engineer |

| Review, reconciliation and distribution of action list report | Project manager |

| Follow up and Updation on Action list | Project engineer/Lead piping engineer |

| Review model and Status files | Design administrator |

Conclusion

No design can be finalized in one shot, there is always review comments and incorporation of new updates. To process this system 30 60 90 model review system was implemented. This system guide us for:

- Requirements and objective about model review milestone.

- Design requirement for each discipline like mechanical, civil, piping. electrical and instrumentation etc.

- Updation of design requirement according to review and guideline.

- Requirement of supporting documents for model review meeting call.

- Roles and responsibility of different person during model review session.